We often don’t think much about what went into our favorite products. If we could peer into those products and see how many people were involved in the product design and development, how many steps were followed, and likely, how many risks were averted, we would be amazed. It is no small feat to take a concept and see it through development.

Behind Every Great Product Is Great Product Design and Development

For innovators, entrepreneurs to large companies and everyone in between, the product design and development process is exciting, a little scary sometimes, and rewarding when it results in a killer product that continually brings in revenue. But those products are remarkably scarce. Many ideas die on the vine, failures from the start because of wrong assumptions, poor data and processes, and the wrong people working on the project. According to one estimate, there are more than 30,000 new products introduced every year, and 95 percent fail.

What does it take to come up with a great product idea and successfully bring it to life? Similarly, what does it take to make an existing product better or extend a product line with a related product that drives value and a new revenue stream?

Start with the End in Mind

A great product is one that consumers want and continually buy. It has value, not just for the developing company or entrepreneur but for the end customer first and foremost. A product you deem valuable to your brand will inevitably fail if it does not bring value to your customer – and enough of them to cover your costs and then some.

Until you know for certain who your customer is and what they need (whether they ask for it explicitly or you create that demand), you will spin your wheels and get nowhere with product design and development.

Analytical Research

Your customer comes first, then the design, then the production. In order to know what your customer will buy, you have to use analytical data that reveals what they are already buying and why, the direct and indirect competition, market trends, where there are opportunities to bring them something new or improved with greater perceived value, and when the best time to bring that idea to market would be. In essence, in order for your product to get their attention, you have to understand the problem you are trying to solve for the customer.

The problem may be that an existing product does not do everything a customer needs. Perhaps functionality is less of a problem, but quality is lacking, presenting you with an opportunity to make a better version that drives out the competition. The product may not even exist yet, but your analysis reveals there is an opportunity to fill that void.

You may even have a product idea that is nearly identical to an existing product on the market but believe you can develop and sell yours at a more attractive price point, or partner with bigger resellers to get it in front of more people.

If you are reselling an existing product on Amazon or making slight improvements on an existing product, it is helpful to use predictive analytics to take trend data and understand the marketplace from a sales velocity, search, ratings and reviews, and pricing perspective. Predictive analytics will tell you about your ecosystem in a predicted way.

RELATED: How to Make Your Product Invention Step-By-Step

You can also take keywords and related words in common search terms to discover what people are looking for and if there is an existing product that matches, uncovering opportunities to fill a niche.

The analytics will tell you how much competition that product may have, plus the key performance indicators (KPIs) to launch your product successfully and get to the top of the search page for more eyes. It helps you decide if your idea is good and if existing product reviews are terrible, how you can take advantage of the opportunity.

User Research

While you can get a lot of information from analytical research, it is always a good idea to test your assumptions in the real world before you take the next step.

Establish test markets to conduct customer surveys and get feedback to see if your hypotheses are accurate. Does your research indicate there is an opportunity for you? What do your customers say they want? What price point do they indicate is viable? How often would they purchase your product? Questions like these will solidify your decision to move forward or not, giving you peace of mind your potential investment of time and resources will be worth the effort.

Whatever angle you take, keeping the customer as your center point will ensure you are designing and developing the right product for the right customer at the right time.

Work with The Right People

Product design is critical in the product development process. This is where you partner with seasoned product designers and engineers to work through every angle of a product idea. Product designers should not just move forward with your rough product sketch or sketch what you tell them to sketch. If you select the right designers, you should be able to lean on them for guidance on what is realistic, manufacturable, and will be cost-effective to build.

Specialized Product Designers

If you want to get the most value from your product design team, you should purposely seek out designers who specialize in designing products like yours. For instance, if you are bringing to market a new athletic shoe, working with a product designer who has an impressive portfolio of athletic shoe expertise will yield a better product faster with fewer revisions than working with a mobile applications designer or general designer with no particular shoe experience.

Specialized Product Engineers

The same thing can be said for the engineers you bring onto the team. Depending on your product, you may need a mechanical engineer, electrical engineer, software engineer and/or other engineering specialist to add to your design team. These engineers will work hand in hand with your chosen designer to optimize the product design, thinking through any potential issues with each iteration, going through what-if scenarios, and putting themselves into the shoes of your customer to determine what they would want in an ideal product based on the data you collected in the research phase.

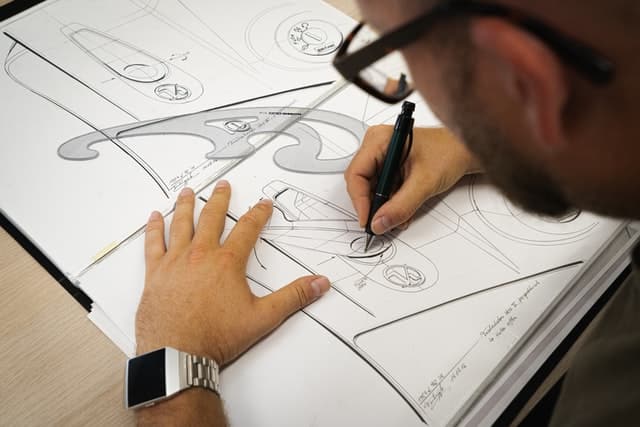

Your design and engineering team will look at every angle and begin the artistic renderings of your product. This begins with sketches and ends with a prototype. There are typically multiple sketch revisions and the final approved sketch may look nothing like what you originally had in mind. That’s often a good thing.

Bringing a product from concept through the design and development process takes a team effort, and if you work with the right people, your initial product concept will have gone through rigorous review and revisions to bring forth the optimal design.

Source Your Factory

Once you have a final design, the next step in product design and development is to find a factory to manufacture your product. Most factories are overseas, particularly in China and Vietnam, presenting unique cultural and logistical challenges for stateside innovators. It is easy to be taken advantage of or start off on the wrong foot when there are language barriers, little on-site governance, and a general manufacturing unawareness.

RELATED: 5 Questions to Ask When Vetting a Manufacturing Partner

Even if your brand has been successfully manufacturing products through an overseas factory for years, it is always a good idea to regularly evaluate the relationship and determine if another factory could manufacture your product faster, better, and at a lower cost. This means you have to be intimately aware of every aspect of the current manufacturing relationship and do your due diligence in assessing your options. It is okay for your existing partner to know you are savvy. It will keep them on their toes and motivate them to continue delivering quality product at a fair price.

As with your product design and engineering team, you want to source a factory that specializes in your product to ensure the highest quality and expertise. Negotiate the price with an eye on the competition. The less it costs you to manufacture a quality product, the greater the advantage you will have over your competition.

Build a Prototype

Once you finalize your product design, it is time to build a sample prototype. You and/or your design and engineering team will work with your chosen manufacturer to develop a prototype. The factory will need the detailed renderings, as well as the materials and components your team determined necessary. Just as you would provide a home builder with detailed architectural designs, you want to be sure your factory understands exactly what they are expected to do and with what elements.

You and your design team will evaluate the prototype to determine if it is what you expected or if more design revisions are needed. Look at every detail, from its appearance to its functionality to its quality of construction. Any potential issues must be resolved at this stage before moving onto the next.

Test and Validate Your Product

With a final prototype approved, you can move into the production phase, but only at a limited capacity. Now is not the time to generate thousands of units. Instead, your goal is to have enough sample products to start selling to early customers to validate demand and price point. Releasing your product in small batches to test markets will help you get more feedback during these early stages.

Engage with your early customers to gather their feedback and use it to improve or modify your design but with cost and manufacturability in mind. You can’t respond to every suggestion, so find trending suggestions or comments that indicate it’s an issue that cannot be ignored.

If there is a feasible way to change your design or manufacturing process to address the issue, work with your designers, engineers, and manufacturer to determine how the product can be further modified to improve its value without significantly impacting costs.

Manufacture Your Product at Scale

Once you have checked all of the boxes, are confident in your final product, and have validated product-market fit with a small initial product run, it’s time to give your manufacturer the green light to scale production.

Using your data you collected in your first product run, you will be able to estimate how many units to produce in each production run going forward. There is a balance between building inventory to meet demand and overstocking inventory that will end up costing you more in the long run. While you don’t want customers to have to wait for their product, you don’t want to be paying for too much warehousing space to house unsold inventory.

A final point on manufacturing. Keep in mind this is a relationship, hopefully a long-term one built on mutual trust. The only way you will know your product is being made with the highest standards and meets any compliance obligations is to go there yourself or hire someone to do it for you. On-site visits to see samples and monitor production quality should be baked into your plan. Quality control includes your product, as well as its packaging. You want everything to be perfect before you pay for shipping.

Manage Your Shipping and Logistics

The final product design and development phase is logistics. This part of the supply chain plays an important role in what you will charge customers for your product. Your goal is to get your product safely and cost-effectively delivered to its end point while maintaining the integrity of the product.

There may be multiple legs in its journey, requiring different modes of transportation. For instance, if you are partnering with an overseas manufacturer, you will need to evaluate your different shipping options, including air, ocean, rail, and road freight. Each will have its own costs and risks, as well as how quickly your product can be delivered. You will likely find that working with a single logistics partner will streamline management and could save you costs.

Begin Your Product Design and Development Journey

The product design and development process is complex. Newer innovators can quickly become overwhelmed with all of the moving parts and seasoned brands often lack all of the resources to develop products as efficiently as they could be produced.

Consider working with a product development company that pulls together the ideal people, best practices and process, and technology all in one place so you get peace of mind you are always on the right track. You can leverage their research, design, production, sourcing, and logistics expertise to bring products to market faster, better, and more predictably with less risk.