You don’t launch a winning product by guessing. You prototype it. Fast, smart, and often.

Developing a strong product prototype is the bridge between your idea and a real product people can use and buy. In this guide, you will learn what a product prototype is, why product prototype development matters, and clear steps to plan, build, test, and improve your prototype so you can move into production with confidence.

Smart teams use prototypes to reduce costly failures, speed up decision-making, and win investor trust before mass production. If your design process still feels like guesswork, it’s time to evolve.

Gembah helps teams build real prototypes that drive results, from idea to factory floor. Talk to us, and let’s turn your product concept into a market-ready MVP.

📩 Book a Product Development Session

TL;DR

Prototyping isn’t optional. It’s your insurance policy, decision engine, and speed multiplier in modern product development. In this guide, you’ll learn how leading brands prototype smarter in 2025 using AI, lean tools, and cross-disciplinary collaboration. You’ll see real examples of how prototyping transforms outcomes, and how to avoid costly rookie mistakes. If you want to ship faster and with less risk, this is your playbook.

Key Points

- Prototypes are not mockups. They’re functional tools that validate your product’s design, usability, manufacturability, and market fit.

- Modern prototyping includes both digital and physical iterations. Smart teams simulate, test, and revise before ever committing to expensive tooling.

- 2025 prototyping trends focus on sustainability, embedded electronics, and AI-driven design tools. Speed + intelligence win.

- Skipping early prototypes leads to late-stage failures. Smart founders build lean MVPs early, test fast, and iterate with discipline.

- Prototypes aren’t just for internal use. They’re your proof of concept for investors, manufacturing partners, and retail buyers.

- Gembah connects you with world-class prototyping partners and guides you from design to production-ready execution.

Also Read:

What Is a Product Prototype?

A product prototype is an early working model of your product that shows how it looks and how it works, but is not ready for full production yet. It is used to test ideas, find problems, and get real feedback from users before you spend money on tooling and manufacturing.

In product development, prototype development lets you move from an abstract idea to a real object you can hold, test, and improve. A good product prototype reduces risk, speeds up decision-making, and helps you prove your concept to investors, partners, and manufacturers.

Why Prototyping Isn’t Optional in Today’s Product Development

The question “what is a prototype in design” has a clear answer: it’s your product’s proof of concept, risk assessment tool, and communication bridge all rolled into one. Modern prototyping serves as the critical link between innovative ideas and market-ready solutions, enabling teams to visualize concepts, test core assumptions, and validate functionality before committing substantial resources.

Creating effective product prototypes helps surface design flaws and usability issues that might otherwise remain hidden until full-scale production. This early detection capability transforms the entire development trajectory, allowing teams to iterate rapidly based on real feedback and technical feasibility assessments. The result is clearer communication among stakeholders, designers, engineers, and investors, which aligns expectations and reduces costly misunderstandings.

Mitigate Risk Before Full‑Scale Launch

The purpose of prototyping extends far beyond simple visualization—it’s about intelligent risk management. Projects with multiple system-level prototype failures show a 26–27% failure rate for hitting design release dates, while projects with thorough prototyping phases successfully meet their deadlines far more often.

Testing with prototypes reveals potential manufacturing challenges and ensures core functions perform as intended, minimizing the risk of post-launch failures. This iterative approach allows for rapid experimentation and validation, which significantly reduces the chance of costly late-stage changes. By surfacing problems early through systematic prototype builds, development teams avoid expensive mistakes, production delays, and reputational damage that can arise from launching unproven products.

Recent industry research demonstrates the tangible impact of early validation. AI-driven features boosted process efficiency for 70% of design teams, while predictive analytics shortened cycles by up to 30%. The process of prototyping serves as a comprehensive safety net where technical, functional, and user experience issues get identified and resolved before significant manufacturing investments.

Investors and Stakeholders Demand Proof

Today’s investment landscape demands tangible evidence of product viability. A well-executed prototype product demonstrates that your concept moves beyond theoretical possibility into practical reality, making it significantly easier to secure buy-in and funding from investors or decision-makers.

Physical or digital prototypes provide concrete evidence of progress and capability, building credibility with stakeholders who need to evaluate multiple opportunities. These working models serve as compelling tools during pitches and presentations, helping communicate value propositions and differentiate from competitors in crowded markets.

Demonstrating a functional prototype reassures stakeholders about feasibility, market fit, and development readiness. This tangible proof accelerates decision-making and investment processes, particularly when coupled with clear documentation of the prototyping phases and validation results.

How to Create a Product Prototype (Step-by-Step)

- Define the product requirements. Write down what your product must do, who it is for, key features, target price, and any safety or quality standards. This becomes the blueprint for your prototype development process.

- Sketch and model your product idea. Create simple sketches and low-fidelity models to explore size, shape, and basic function. Use paper, foam, or simple 3D CAD models to quickly test different options before you build a full product prototype.

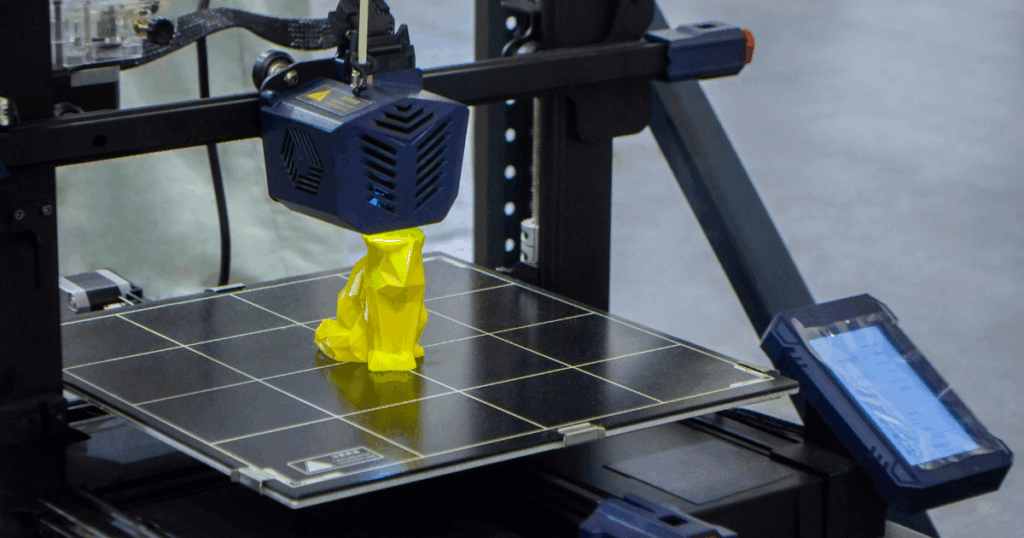

- Choose materials and manufacturing methods. Decide what materials you will use for your first functional prototype and how it will be made, such as 3D printing, CNC machining, or simple hand-built parts. Match your choices to the final product as closely as your budget allows.

- Build a functional product prototype. Create a prototype that shows how the product will work in real life, not just how it looks. Focus on core functions first so you can test performance, durability, and user experience.

- Test the prototype with real users. Put the product prototype in front of users who match your target customer. Watch how they use it, collect feedback, and document issues with comfort, usability, and reliability.

- Refine and iterate the prototype. Use test data to fix problems, adjust features, and improve the design. Repeat the prototype development cycle until you have a version that meets your product requirements and is ready for production planning.

- Plan the path from prototype to production. Once your product prototype works, work with manufacturers to choose final materials, tooling, and production processes. Lock in drawings, tolerances, and tests so the final product matches your best prototype.

Major Prototyping Trends Reshaping 2026

The landscape of prototype design tools and methodologies continues evolving rapidly. Virtual prototyping market value in 2025 is projected to reach USD 6.14 billion, with sustainability as a major adoption driver. Advanced digital modeling reduces material waste and resource expenditure while enabling more sophisticated testing scenarios.

Simultaneously, rapid prototyping is expected to hit USD 3.25 billion in 2025 with a compound annual growth rate of 20.07% through 2030. This explosive growth reflects the increasing recognition that rapid iteration and validation drive competitive advantage across industries.

Industry leaders have embraced data-driven approaches to prototyping that deliver measurable results. Incorporating AI in prototyping has enabled a ~30% reduction in product development costs in automotive and aerospace industries, while AI-powered prototyping and simulation tools are credited with cutting time-to-market by up to 50%.

Growing Focus on Sustainability

Environmental consciousness has moved from nice-to-have to business-critical. Sustainable materials and practices—including bioplastics and recycled filaments—are being rapidly adopted in prototyping, with startups reducing plastic waste through biodegradation and recycling initiatives.

The shift toward sustainability reflects broader market demands and regulatory pressures. Industry research finds that up to 80% of a product’s environmental impact is determined during initial design and material sourcing, prompting widespread use of sustainable prototyping platforms.

Teams now explore renewable, recycled, and biodegradable materials to reduce environmental footprints of both prototypes and final products. This includes minimizing waste through optimized design iteration cycles, evaluating lifecycle impacts during early development stages, and considering end-of-life recyclability from the earliest prototyping phases.

Real-World Success Stories: Prototyping in Action

Leading companies have demonstrated the transformative power of strategic prototyping through measurable business outcomes. These case studies illustrate how different industries leverage rapid prototyping to achieve competitive advantages and accelerate innovation cycles.

Medtronic: Accelerating Medical Device Innovation

Medtronic faced significant challenges in their surgical implant development process, where traditional prototyping cycles took months and delayed product launches in highly competitive markets. The medical device giant needed to accelerate design validation while incorporating real-time clinical input from surgeons and meeting strict regulatory requirements.

In early 2023, Medtronic implemented advanced 3D printing and additive manufacturing for rapid prototyping across their surgical instrument and implant lines. This transformation enabled quick iteration of device designs, testing of new materials and geometries, and incorporation of clinical feedback within days rather than weeks. The company integrated these capabilities directly into their product development pipelines by late 2024.

The results proved transformative for Medtronic’s development process. Cut prototyping lead times by over 70% from several weeks to just 2-4 days, the company achieved FDA pre-market submissions months ahead of previous schedules. This acceleration contributed to reported annual R&D savings of 18% in key product lines while improving clinical trial outcomes and enabling successful launches ahead of major competitors.

General Motors: Revolutionizing Industrial Hardware Production

General Motors confronted costly downtime and manufacturing inefficiencies caused by their reliance on custom-machined aluminum parts for overhead conveyor hangers. These heavy components required lengthy production times and created operational bottlenecks that threatened manufacturing schedules and profitability.

GM’s solution involved deploying Stratasys F900 3D printers with FDM Nylon 12CF to rapidly prototype and produce conveyor hangers. The switch from aluminum to high-performance polymer composites allowed for faster iterations and functional testing directly on factory lines, enabling real-time validation of design improvements.

The prototyping-to-production approach delivered impressive results starting in mid-2023. Reduced weight of hangers by 32%, improving ergonomics and reducing mechanical wear, while achieving 80% time savings in production from weeks to days for each batch. Most significantly, GM prevented days of unplanned manufacturing downtime, saving several million dollars annually while establishing rapid iteration workflows for future tooling and fixture designs.

Supermodelli: Enabling Consumer Electronics Innovation

Major electronics producers including Intel, Apple, and Panasonic faced mounting pressure to deliver high-fidelity appearance models for new devices on increasingly compressed timelines. These companies needed photo-realistic prototypes for marketing campaigns, trade shows, and investor presentations while maintaining the visual and tactile quality expected by executive teams and public audiences.

Supermodelli specialized in addressing these challenges through rapid, photo-realistic prototyping using advanced CNC machining, painting, and finishing processes. Their approach delivered prototypes tailored specifically to visual and tactile requirements for executive demonstrations and public previews, often with turnaround times under a week for critical projects.

Since establishing partnerships in 2022, Supermodelli has consistently delivered measurable value for high-profile device launches. Cut pre-market model production times from an industry standard of 3-4 weeks to under 5 days for rush jobs, enabling clients to meet critical marketing and funding milestones. The superior product demonstrations facilitated by these prototypes helped secure hundreds of millions in pre-orders and early investment rounds through compelling live demos for major product announcements.

Core Best Practices for Effective Prototype Design

Successful prototype product design follows proven methodologies that maximize learning while minimizing resource waste. The most effective approaches align prototyping techniques with specific project objectives, ensuring each iteration delivers meaningful insights that drive product development forward.

Clearly Define Purpose & Scope

Establishing clear objectives for each prototype—whether validating form, function, user experience, or manufacturability—ensures focused and efficient development. The purpose of a prototype must be explicitly defined before any design or fabrication work begins, preventing scope creep and resource misallocation.

Defining scope helps allocate resources appropriately while preventing unnecessary complexity that can cloud validation results. Development teams should align on what specific questions each prototype needs to answer and what critical decisions it should enable before moving to the next development phase.

This clarity becomes particularly important when determining how to build a prototype that serves multiple stakeholder needs. Early-stage prototypes may prioritize quick idea validation using low-fidelity models, while later iterations require high-fidelity representations that accurately reflect full functionality and appearance.

Leverage Collaborative Approaches and End-User Involvement

Modern prototyping increasingly emphasizes direct involvement of end-users through co-creation sessions. Products developed this way show a 25% higher adoption rate, demonstrating the significant value of participatory design approaches. This trend reflects growing recognition that user insights gathered during prototyping phases translate directly into market success.

Device diversity has become a critical consideration, with 55%+ global mobile usage driving teams to test prototypes across multiple devices early in development. This multi-platform approach ensures responsive, platform-consistent experiences that meet modern user expectations.

Internal feedback culture plays an equally important role, with executives emphasizing regular team critique sessions as a cornerstone of quality improvement. Frequent feedback cycles correlate strongly with enhanced design quality and help identify potential issues before they become costly problems.

Material and Process Selection Aligns with Testing Goals

Choosing appropriate materials and prototyping methods that match intended testing objectives remains critical for generating meaningful results. Early-stage prototypes may utilize low-cost, easily modifiable materials that enable rapid iteration, while later versions should employ materials and processes that mirror production realities.

The selection of specific prototyping tools and techniques—whether 3D printing, CNC machining, or hand fabrication—should be based on required speed, fidelity level, and relevance to the final product specification. Design prototyping software increasingly enables teams to evaluate multiple material and process options before committing to physical builds.

This strategic approach ensures that each prototype delivers maximum value for its intended purpose while building toward production-ready specifications. Teams must balance speed and cost considerations against the need for accurate representation of final product characteristics.

Design for Manufacturing (DfM) Integration

Integrating DfM principles into prototyping phases ensures that designs remain feasible, cost-effective, and scalable for mass production. Prototypes should account for assembly requirements, material constraints, and production tolerances to avoid surprises during manufacturing transfer.

Toyota integrated DfM into its prototyping and production systems by designing components for use across multiple models, minimizing part variety and reducing supply chain complexity while achieving notable cost savings. This approach demonstrates how DfM-driven prototyping can contribute directly to long-term product success.

aPriori documented several cases where engineering teams adopted DfM using digital manufacturing simulation tools during prototyping, allowing designers to identify and mitigate cost drivers early while improving sustainability. More than 70% of part cost was optimized at the design stage through this approach.

Early collaboration with manufacturing partners or engineers helps identify potential production issues and streamlines the transition from prototype to scalable manufacturing. This integration prevents costly redesigns and ensures that innovative concepts remain manufacturable at commercial volumes.

Navigating Common Prototyping Pitfalls

Even well-intentioned prototyping efforts can encounter significant challenges that undermine their effectiveness. Understanding these common pitfalls helps development teams maintain realistic expectations while implementing strategies to minimize risks and maximize learning opportunities.

Over-Engineering Early Prototypes

Many teams fall into the trap of creating overly complex early prototypes that consume excessive resources without delivering proportional insights. Early-stage models should focus on validating core assumptions rather than perfecting every detail, allowing for rapid iteration and learning cycles.

The temptation to build production-quality prototypes too early often stems from stakeholder pressure or perfectionist tendencies. However, this approach typically leads to slower feedback loops and higher costs without necessarily improving decision-making quality. Maintaining discipline around prototype fidelity levels ensures resources are allocated efficiently across development phases.

Insufficient User Testing Integration

Prototypes developed in isolation from end-users frequently miss critical usability issues and market fit problems that become expensive to address later. The most effective prototyping processes incorporate user feedback at multiple stages, enabling teams to validate assumptions and adjust directions before committing to advanced development work.

Scheduling regular user testing sessions throughout prototyping phases, rather than treating testing as a final validation step, helps surface issues when they’re easier and less expensive to address. This iterative approach reduces the risk of fundamental design flaws making it through to production phases.

Inadequate Documentation and Knowledge Transfer

Poor documentation practices during prototyping can lead to lost insights and repeated mistakes as projects transition between teams or development phases. Maintaining clear records of design decisions, test results, and lessons learned ensures that valuable knowledge accumulates rather than disappears with team changes.

Establishing standardized documentation processes early in prototyping phases prevents information gaps that can undermine later development efforts. This includes capturing not just what worked, but also what didn’t work and why, providing valuable guidance for future iterations and related projects.

Prototyping Budget & Cost Management

Understanding prototype development costs enables better resource allocation and project planning. Prototyping cost ranges by method and complexity vary significantly: 3D printed prototypes generally cost between $100 and $5,000, while high-end engineering prototypes can range from $10,000 to over $250,000, especially in sectors like aerospace and medical devices.

Understand Core Cost Drivers

Prototype costs are influenced by complexity, material choice, fidelity level, and the number of iterations required. Labor expenses, specialized tooling requirements, and the need for custom components can significantly affect overall budget allocation. Recognizing which aspects contribute most to total cost helps prioritize spending and avoid unnecessary expenses.

CNC machined metal prototypes cost around $80–$200 per hour plus material expenses, with materials like aluminum and stainless steel adding $25–$90 for standard sheet sizes. Understanding these baseline costs enables more accurate budget planning and vendor selection.

Optimize Through Early Design Validation

Validating key assumptions and design choices with early, low-cost prototypes prevents costly rework in later development stages. ROI of early prototype validation shows that virtual prototyping and early validation can reduce physical prototyping and rework costs by up to 30–50% across industries.

The financial impact of strategic prototyping extends beyond direct cost savings. Virtual prototyping also supports quicker time-to-market, providing additional ROI by capitalizing on market opportunities earlier than competitors. This timing advantage often translates into substantial revenue benefits that justify prototyping investments.

Iterative feedback loops and rapid testing help identify critical flaws before investing in high-fidelity or production-grade prototypes. This approach enables teams to catch and correct design issues before manufacture, resulting in faster development cycles and significant cost savings over traditional linear development approaches.

Prototyping Across Industries: When to Prototype What

Different industries require tailored approaches to prototype product design, reflecting unique regulatory requirements, user expectations, and technical constraints. Understanding these sector-specific needs ensures that prototyping efforts align with industry standards and market realities.

Consumer Electronics & IoT

Prototyping in consumer electronics focuses on both physical form and integrated digital functionality, including connectivity, user interface design, and hardware-software integration. Rapid prototyping can reduce time-to-market by enabling swift development, immediate testing, and rapid iteration, substantially accelerating product launch cycles compared to traditional approaches.

Fast-moving consumer markets demand accelerated prototyping cycles to stay ahead of trends and respond effectively to user feedback. Iterative models test ergonomics, user interactions, and system integration before committing to production tooling and manufacturing investments.

The convergence of physical and digital elements in consumer electronics requires prototypes that accurately represent both hardware performance and software functionality. This comprehensive approach ensures that final products meet user expectations for seamless, intuitive experiences.

MedTech & Regulated Devices

Medical device prototyping must address strict safety, usability, and compliance requirements from the earliest development stages. Core regulatory requirements include FDA regulations (notably 21 CFR 820 and device-specific guidance), ISO 13485:2016, and EU MDR standards that govern prototype development and testing.

Design controls and documentation must be implemented throughout prototype phases, including design planning, inputs, outputs, verification, validation, and design review processes. Risk management becomes integral throughout prototyping, involving hazard identification, risk analysis, and mitigation strategies as required by regulatory frameworks.

Functional prototypes serve multiple purposes in regulated industries: clinical testing, regulatory submissions, and validation against industry standards. Documentation and traceability remain critical throughout the prototyping process to meet regulatory expectations and support market approval processes.

Industrial Hardware & Machinery

Prototyping for industrial applications emphasizes durability, performance under stress, and compatibility with existing systems and workflows. Prototypes may include scaled models, functional assemblies, or specialized test rigs to validate mechanical, electrical, and operational parameters under realistic conditions.

The focus centers on ensuring reliability, maintainability, and manufacturability in demanding industrial environments. An automotive OEM, with support from ATS Industrial Automation, confronted prototyping challenges in scaling laser welding for new battery modules, applying DfM principles to modify materials and refine processes while ensuring manufacturability.

This intervention enabled safe scaling from 100 to 1,000 modules per day while preventing costly delays and rework. Such examples demonstrate how industrial prototyping must balance innovation with proven manufacturing processes and operational requirements.

Learn:

More About Our Product Protyping Solutions

End-to-End Supply Chain Solutions.

How Gembah Supports Best-in-Class Prototyping

Gembah’s comprehensive platform addresses the complex challenges of modern prototype product design through expert guidance and access to a vetted network of over 600 designers and 2,000 factories. This extensive ecosystem enables clients to navigate every stage of the prototyping process with confidence and efficiency.

The platform offers specialized prototyping services including concept refinement, 3D modeling and technical drawings, advanced prototyping technologies, and development of both functional and virtual prototypes. Machine learning technology optimizes workflows and eliminates traditional inefficiencies, making the prototype design process faster, cheaper, and more efficient than conventional methods.

Gembah’s approach emphasizes strategic alignment between prototyping objectives and business goals. The platform supports material selection, DfM integration, and iterative design processes that help teams move efficiently from initial concepts to production-ready prototypes. Collaborative tools facilitate communication, documentation, and feedback collection, streamlining development cycles while maintaining quality standards.

Recent client successes demonstrate this comprehensive approach in action. Gembah partnered with Kate Bray and B to develop a women’s health device that provides cramp relief, managing everything from expert guidance on product development and electrical engineering to compliance requirements including UL certification. The project achieved over 1,000 pre-orders and strong viral marketing traction, with market launch scheduled for early 2025.

By leveraging industry expertise and scalable manufacturing partnerships, Gembah helps clients achieve high-quality prototypes that align with business objectives while minimizing development risks and optimizing resource allocation.

Conclusion

Here’s the hard truth: Without smart prototyping, you’re burning money.

The brands that win in 2025 are stress-testing their products early, validating with users, and learning fast. Prototyping isn’t just a phase. It’s a system for risk management, speed, and insight.

Gembah gives you the playbook, the people, and the partners to make it real. From digital CAD to factory-ready prototypes, we help you build with confidence, not chaos.