Bringing a new product to market is a complex and challenging process that requires careful planning, execution, and attention to detail. For every fidget spinner, Croc, and iPhone, there are hundreds upon hundreds of consumer goods still sitting in a warehouse.

Product development failure isn’t exclusive to start-ups and entrepreneurs—SMBs, mid-market companies, and even global enterprises all miss the mark in devastating fashion.

Look no further than the recent failures of Google Glass and Theranos, or the decades-old flop that was Sony Betamax. Despite the best efforts of experienced product development teams, many products fail to meet consumer needs, suffer from quality issues, or simply do not perform as expected.

In fact, statistics show 95% of these products fail, and 40% never become profitable.

Why does this happen? Because companies fast-track product production and marketing processes before perfecting the product development process itself. They try to beat their competitors to market with products that customers don’t need or want.

In this article, we will explore the key components of a winning product development process, as well as some key considerations and tips to keep in mind as you look to bring your new product to market.

What is Product Development?

Product development is the culmination of sequential steps that turn an idea or product concept sketch into a physical product that fills a gap in the current market. Gartner defines it as “the process of transforming ideas into valuable solutions.”

“Solutions” is a great word to describe the end result of the product development process because, if done correctly, you’re creating a new product that should solve an existing problem for consumers. The cordless vacuum solves the issue of range limitations. The selfie stick allows people to take better group photos with their mobile phone. And the taco holder stand speeds up the assembly process.

While each of these solutions was novel at the time, they are now household products because their creators did one critical thing:

They approached the product development process with the customer’s challenges in mind.

In fact, entrepreneurs and SMBs often make the best products out of their frustrations with either an existing product or lack of solution for a consistent issue.

The product development process provides the structured steps by which these frustrations are transformed into a product that is essential in the day-to-day lives of countless people.

How Development Fits into the Product Life Cycle

The product life cycle is a series of phases that all physical and digital goods go through—from concept to commercialization to discontinuation. It’s a systematic and structured approach to creating a new product and bringing it to market until it no longer meets the needs of customers or becomes outdated.

The product life cycle begins with the development, the focus of this article, but it then progresses into 4 other other phases:

Introduction: You put your go-to-market strategy in action and get a first glimpse at whether or not your product meets the needs of customers. Sales start off slow and increase as you implement marketing and business development strategies.

Growth: If your product really resonates with consumers, sales begin to take off as your marketing and sales efforts are boosted by word of mouth and virality. This is also the stage where competitors typically emerge with similar products.

Maturity: Sales growth plateaus and even begins to decline, though overall sales and revenue may continue to increase. Near the end of this stage, your product may experience a decline in sales and you’ll need to decide whether to iterate your product or develop a new one.

Decline: Most products experience a decrease in both sales and market share as time progresses. It’s important to have a strategy in place to ramp down marketing, sales, production, and logistics efforts, so you can quickly move to either iterate or sunset your product.

While product development appears as just the first step in a long journey, it’s by far the most important. Without following a rigorous product development process, it’s unlikely your ideal will ever pass the introduction stage, let alone reach maturity.

Understanding the 8 stages of the product development process outlined below is a great first step towards creating a product that profitably progresses through the full life cycle.

Stages of the New Product Development Process

1. Customer and Market Research

The whole purpose of product development (creating a new product) is to meet the current needs of customers by filling a void in the market or significantly improving on an existing product. This requires a thorough understanding of your ideal customer and the competitors in your niche.

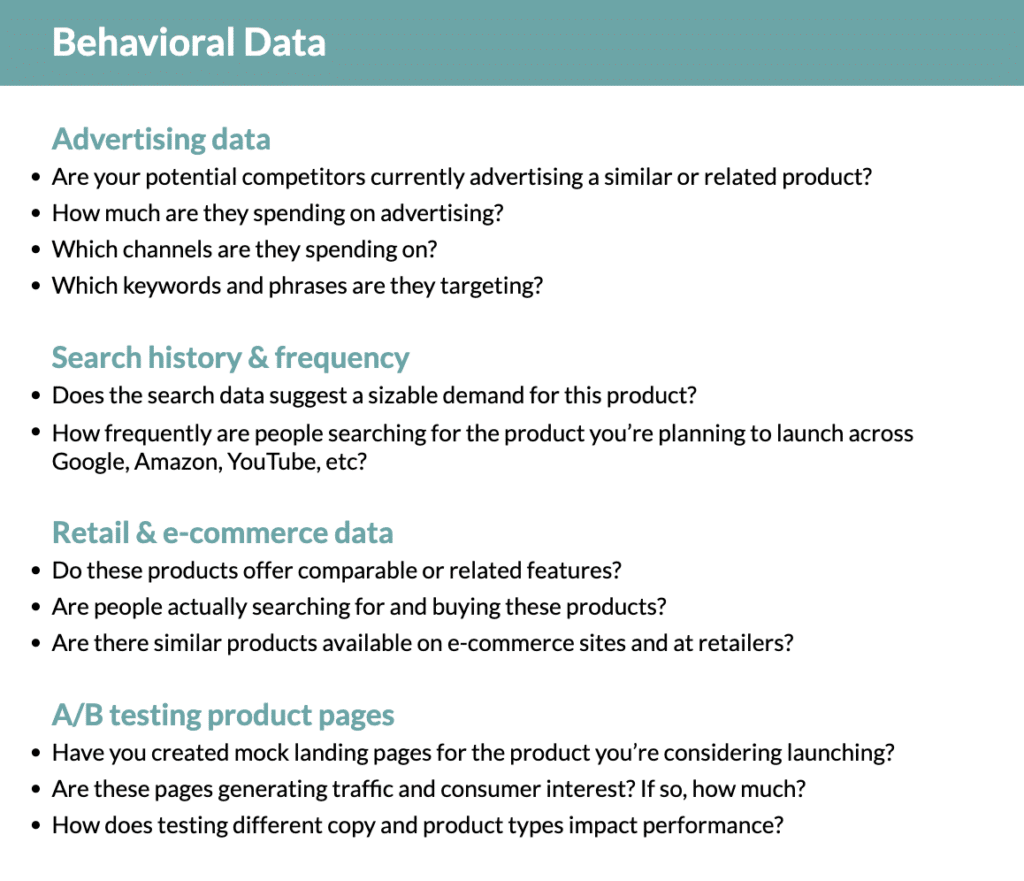

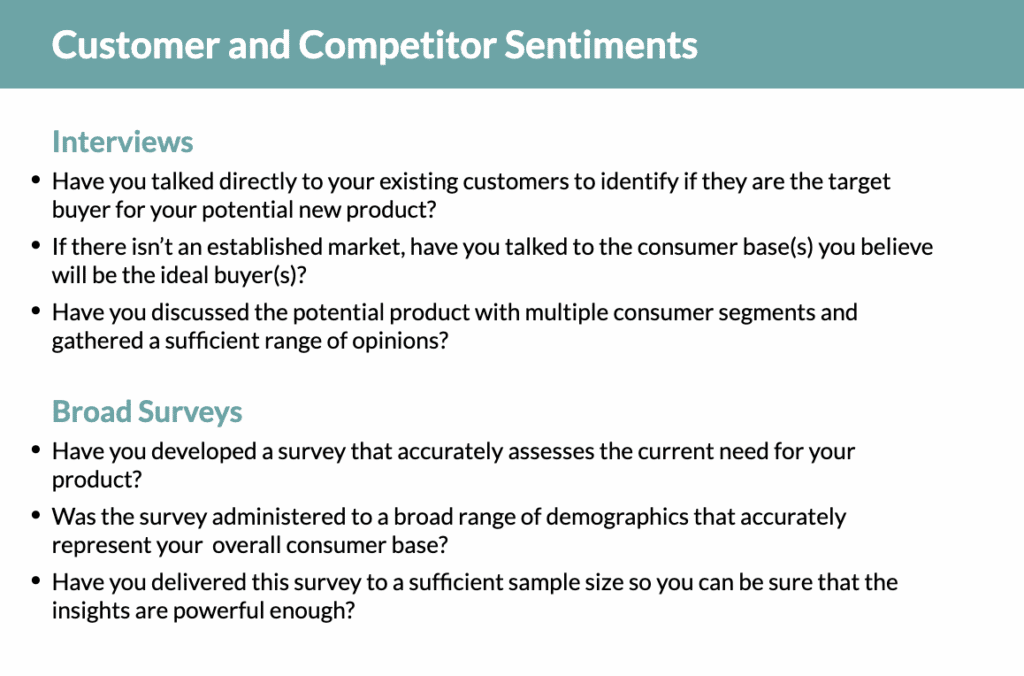

To understand whether there is truly a need for your potential product, you need to thoroughly research the behavior and sentiments of your customers. You also need to identify who your competitors are in the current market.

Collecting this data throughout your research process will help you answer the ultimate question: “Will it sell to your target market?”

Here are some of specific questions you need to ask yourself to ensure you’ve collected enough data to make an informed decision:

Interviews and surveys are particularly important during this stage because they provide a balance between granularity and volume. With multiple levels of analysis it gets easier to spot trends and identify who will (and will not) be best served by your product.

Importantly, these data points also offer you opportunities to improve the product prior to manufacturing or identify key selling points that will pique customer interest during the marketing and sales stages.

Using the data from both types of research will help you decide whether your product has a large enough market to generate a return on investment, enhance your brand value, and sustain sales through a lengthy product life cycle.

2. Ideation and Initial Design

Now it is time to define the “how” for your product. This is where your napkin sketch, shower idea, or vision of a new disruptive technology turns into something tangible — you start to develop the features in your product. This stage of the product development process is also known as conceptual design, preliminary design, product design, or industrial design.

The best way to start the product development process is with ideation—an interactive process where you create quick sketches of both what the product looks like and what it does. This often involves creating multiple drafts and mock-ups. What separates the good products from the great ones is a balance between aesthetic appeal and functionality. But remember, when it comes down to it, functionality is still the top priority.

You then compare these different concepts against your customer and market research to identify a shortlist of top designs. Continue to modify that design and iterate at a high level until your product has what it needs and nothing more.

3. Product Engineering and Feasibility Study

The product engineering stage is essentially where you further vet the initial product design to determine the likelihood that it can both meet the needs of your customers and generate revenue for your business.

Up to this point, your product development team has been defining things at a higher level of abstraction—now it’s time to focus on the details in a strategic, meticulous manner.

Product engineering means defining a manufacturable product that has all of the desired features and functions to meet customer needs. The output from the engineering step is a complete definition of your product, also known as the detailed design. This will include aspects of the final product like:

- Physical shape and size

- Number of components

- Engineering of components

- Product materials and fastening

- Colors and surface finishes,

- Software and electronic components

- User interface and accessibility

Depending on the nature of your industry and the final product, you may require more details.

A lot of decisions need to be made during this stage of the product development process, and the most important thing you need to do is ensure all of those decisions create enough value to convince your customers to buy the product.

Many entrepreneurs underestimate how much effort goes into product engineering. If you don’t take the time to do it right, you won’t end up manufacturing the product you designed. Or worse, you may end up defining a product that can’t be made at all.

That’s why, before jumping to the concept development and testing phases of the product development process, it’s important to understand whether or not the product you’re planning to launch is feasible. You know that the product is possible, but does it make logistical sense to create this product?

If it doesn’t, you risk investing time and resources into a plan that will never see the light of day.

Determining the feasibility of your product can help you avoid this waste.

Feasibility Study

During a feasibility study, you identify challenges, explore costs and timing, and truly answer the question, “should we actually build this?”

There are typically six stages in a new product development feasibility study:

- Ideation & Research

- Product Design

- Sourcing

- Production Management

- Logistics & Compliance

- Supply Chain Management

Across each stage, you’re assessing whether your new product makes sense from an engineering, finance, and customer experience perspective. You challenge your initial product, and all involved processes, with the following questions:

- How much effort (and budget) will it take to go into product design?

- Are there people that can actually make what you’re planning to create?

- Where could production potentially fail and can you get ahead of it?

- Once the product is produced, can you deliver it to warehouses, stores or front doors?

- Will your product meet all regulations in the regions you plan to sell?

- How effectively will your product scale?

Get creative in finding solutions to every pitfall your team can think of, even if there’s only a marginal chance it may happen in a real-world setting. If you’re looking for support with running your own feasibility study, the best practice is to involve third-party experts who have experience in the different stages of the product development process.

When your study is complete, you’ll have a clear picture of what to prioritize during product development, what potential problems may arise, and a plan in place for growth and scaling.

4. Identify Manufacturing Partners

Around the time you start engineering and feasibility testing, you also need to search for the people who will bring your product to life—manufacturing partners.

This company, or network of companies, will take your design and turn it into something you can see, touch, and, most importantly, sell. Consulting with these experts, or other third-parties, during the engineering process can help speed up product development and reduce errors.

Remember, in the same way you vet your own product, you should also vet your manufacturing partner.

If you don’t know what capabilities they have and what they charge, you’re setting your product development process up for failure. Plus, fixing those mistakes when you are trying to ramp up production is the most expensive way to go.

5. Prototype Development

As soon as your product definition is solid enough, your team should start building prototypes. Having a physical model of your product will help answer questions about the design and bring you one step closer to your final product.

You can see how it looks, test its performance, get opinions from potential customers, and explore different solutions. A prototype can be as simple as a cardboard cutout, a digital mockup, a physical model made with easily shaped materials or 3D printing, or a working prototype made by your manufacturing partner.

This iterative process is part another benefit of working with your manufacturing partner early and should be built into the product development process used by your team.

6. Testing and Iteration

The testing and iteration phase of the product development process involves several sub-steps, including:

Planning: The first step is to plan out the testing process, identifying the specific tests that will be performed, the metrics that will be used to evaluate the product, and the resources needed to carry out the testing.

Testing: Actual analysis of the product using the planned tests. The results of the testing are recorded and analyzed to identify any issues or areas that need improvement.

Iteration: Based on the results of the testing, changes are made to the product to address any issues or improve performance. These changes may involve modifying the design, adjusting the features, or fixing any bugs that were identified during testing.

Re-testing: After changes are made, the product is re-tested to ensure that the changes have been effective and that there are no new issues that have arisen as a result of the changes.

Repeat: The testing and iteration process is repeated until the product meets the desired level of quality and performance.

The best products go through several iterations of testing before the final product is developed. The goal is to identify and fix any issues or areas of improvement in the product to ensure that it meets the needs and expectations of the intended users.

7. Production Planning

The production planning step starts during the final stages of the engineering and prototyping. Production planners, manufacturing engineers, quality engineers, and supply chain experts help take the complete product definition and turn it into the three key components:

- Production plan: An internal document that outlines all processes and resources involved in the creation of your product—including materials, equipment, manufacturing processes, scheduling, capacity, staffing, and cost.

- Supply chain map: A visual representation of the different entities that will be involved in the production of your product at different stages—including suppliers, manufacturers, distributors, and retailers.

- Quality system: A detailed document outlining the processes and personnel involved in assessing and maintaining the quality of your manufactured products.

During this stage, you ensure that all off-the-shelf components are sourced, custom tools are designed and ordered, each step in manufacturing is laid out in detail, and an inspection and tracking system is put into place for quality assurance.

8. Product Manufacturing

After completing these previous steps, it’s finally time to start manufacturing and creating your newly-developed product at scale. But that still doesn’t mean your product development team is off the hook.

The product production process, like most of the product development stages, is an iterative and interactive process.

Use an approach like lean manufacturing to continuously improve and remove waste from every link in your supply chain and every step in your production plan. Quality should be measured and tracked to drive the right improvements. You also need to hold everyone accountable for meeting cost, schedule, and quality projections.

Key Considerations for Your Product Development Process

Closely monitoring the progress of your new product as it moves through the 8 stages of the product development process is the essential precursor to success—but it’s also the bare minimum.

There are countless considerations you need to make throughout the product development lifecycle to increase your chances of success.

Here are a few of the key considerations that will increase your chances of creating a product that people will actually want to buy.

Remember: Your Product Needs to Sell

It would be a much better world if products could sell themselves—and a fantastic product is certainly easier to sell than a run-of-the-mill one. However, you still have to introduce it to the market, educate them on it, and then facilitate the purchase from your key customers.

There are lots of avenues for getting your product into the hands of your customers. That’s why, while you perform customer and competitor research, you also need to explore the best way to market and sell your product.

Develop a go-to-market strategy that includes a marketing plan, what your sales and distribution looks like, and how customers will buy from you. Also ask yourself how you will use social media, e-commerce, and digital marketing to reach your target market.

Connecting Your Product to Your Brand

Make sure to incorporate the company branding into your product design. Branding can drive a design, and a design can drive branding—they feed off each other. The aesthetics of your product or the user experience during product interactions can all be a reflection of branding. It will undoubtedly be a part of your packaging as well.

Branding is about customer experience and emotion as much as product fit, form, and function. Take some time to look at iconic brands like Apple, Nike, Gucci, and the leaders in your space. Now think about how their designs reflect the strength of the brand and vice versa.

Intellectual Property Protection

The better your product, the more people will want to copy it. So, an essential part of bringing your idea to market is protecting your intellectual property (IP) through patents, trademarks, and trade secrets.

And don’t forget that there may be IP in your manufacturing processes as well as your product design. As a business owner, you are also trying to build assets for your company, and intellectual property can be very valuable to any investors and other stakeholders.

Logistics

You need to get your product from where it is made to the customer, most likely with stops along the way. Logistics is about shipping, warehousing, and delivering products to their final destination. You need to set up your logistics network so products are where they need to be when they are needed.

This is something you should work on in parallel with your production planning, with the goal of your logistics being reliability, flexibility, and security.

Customer Support and Repair

Once your product is in the hands of your customers, they are going to have questions and undoubtedly issues will arise. No matter how good your design is, some of your products will need repair or replacement. Plan this important part of your business and scale it as your sales go up, so poor customer experiences can be rectified as quickly as possible.

The Role of Product Managers

Product managers play a critical role throughout the product development process, from the initial product idea through to the final product and market launch. The key responsibility of a product manager is to act as the bridge between the product development team, other internal stakeholders, and the target market.

In the early stages, they conduct market research and a SWOT analysis (assessing strengths, weaknesses, opportunities and threats) to validate the product idea and ensure it aligns with company objectives and customer needs. As the process of developing a product progresses, they work closely with engineering, design, marketing and other teams to define requirements, prioritize features, and make strategic decisions.

The product manager is the central point of communication and keeps everyone aligned on the product vision. It’s important to understand the difference between product development and product management – while product development focuses on the hands-on creation of the product, product management involves the strategic planning, execution and oversight of the entire product lifecycle from conception to launch and beyond.

6 Tips to Get the Most Out of Your New Product Development Process

1. Don’t Skip (or Skimp) on the Steps

This tip goes first because it’s where most new product development projects make their biggest mistake: Most companies, especially those who have existing products on the market, like to jump as quickly as possible into manufacturing.

And you can do that, but you’ll likely end up paying a lot of money down the road—whether it’s to reengineer components you can’t produce, or after you realize that your customers don’t really need the product.

Take the time to do a complete business analysis, a feasibility study, and document your marketing strategy. In design, take the time to develop a final product design that is manufacturable, addresses customer needs, and hits your cost and price goals.

When you look at the other hints, you will notice they overwhelmingly address the product design phase of the new product development process—this is because so many people skimp during the design steps and have that choice come back to haunt them.

2. Prototype Early for More Efficient Improvements

If you talk to any experienced product development experts, they will say, “It’s always more cost effective to make changes early.” This is one of those basic facts of the industry, but not nearly enough people pay attention to when the moment comes.

As you work your way through the product development process, you will solidify aspects of marketing, design, manufacturing, and distribution. And once something is solidified, changing it takes time and money.

The best way to do this is to start with thorough research in the first phase. Spend the time and money to do market research, gather market needs, brainstorm product concepts, and validate your product idea regarding customer needs and commercialization. It’s tempting to dive into the design before this is all done, but you will have to start over again once you get all your information in one place.

Then, in the early stage of the product design phase, build prototypes as early as possible and test them internally and with target customers. At the very least get them into the hands of a proxy product owner.

The more information you get from mockups, both real and virtual, the easier it will be for you to incorporate what you learn into the design. So make sure you do this early and often.

And don’t forget manufacturing. Sharing your prototypes with your production partners will allow them to give you feedback on design changes before spending any time or money on manufacturing processes or tooling.

3. Adopt a Lean Product Development Process

There are many ways to implement the new product development process. Some methods have similar phases but different tasks for each team member. Different product development processes will vary how your team approaches creativity, problem-solving, product management, market input, collaboration, and manufacturing.

Lean product development is one of the most effective approaches for creating physical products. The method was developed by automotive giant Toyota and is now used across industries by many of the best companies in the world. This approach is especially popular with startups and smaller companies or teams that can work together in the iterative manner prescribed by this approach.

The principles of lean product development are:

- Understand and capture value

- Eliminate waste

- Create and capture knowledge

- Use concurrent engineering

- Create a value stream

- Pull information through the value stream

- Perfect both the product and the process

The goal of this approach is to work as a tightly integrated team, focused on product and process innovation to increase the amount of value your end products provide paying customers.

4. Use Design for Manufacturing

Every tip mentioned here is important, but using design for manufacturing (DFM) is the only one that is absolutely required. If you don’t use DFM, the best outcome is that your product will be expensive to make.

The worst, and more likely, is that it won’t be manufacturable.

The most important recommendations in DFM are:

- Have your manufacturing partner review your design and prototypes and make recommendations on improving the design to increase manufacturability and lower cost.

- Design the geometry of parts with manufacturing and assembly processes in mind.

- Minimize the number of parts in any assemblies.

- Use the same parts as much as possible.

- Design parts to minimize the amount of labor in manufacturing and assembly.

- Remove pre-processing, manufacturing, and post-processing steps.

- Minimize the need for tight tolerances.

The list goes on.

The key thing to remember is to build design for manufacturing into your new product development process and make sure everyone on your product development team is applying it throughout your project.

5. Create a Minimum Viable Product (MVP)

If you are working on a brand new product, the best way to get feedback and fine tune your marketing plan is to get your product on the market and in the hands of customers. Research can get you close, but you get your best input from your target market after a product launch.

That’s why the concept of a minimum viable product (MVP) has become such a popular product strategy. It’s a concept developed for software development that suggests creating a product with the minimum number of features, just enough to start getting customer feedback in the real world.

Still, the minimum viable product concept works well in physical products, giving you valuable user feedback so that in future versions of your product, you can make tweaks to the product design to meet a greater number of market needs. A minimum viable product is also a great way to try out your messaging and gather metrics on how well your marketing plan reaches your target audience.

6. Assemble a Team of Expert Service Providers

This tip might seem kind of obvious—why wouldn’t you hire an experienced product development team that knows how to cooperate?

The reality is, when you’re building your team, you can often get focused on specific needs for your specific product and forget general requirements like getting domain experts on your team.

Be deliberate and make sure you’re not picking someone because they can put oil on the latest squeaky wheel.

We go with an expert all too often because no one knows what they know or who they know. And then we find out that they are impossible to work with, and your whole project goes off the rails. Hire employees and pick consultants and partners based on your overall needs as well as specific ones.

Ideally, you can find vetted expert product developers with a track record of success.

Find the Right Partners for Your Product Development Process

If you have not brought a product to market before, this might seem more than a little overwhelming.

But don’t worry, every single product you buy goes through the exact same growing pains. What’s more, there are people out there who do this every day, and they do it well. You can hire certain key experts to be part of your team, but you also need outside people with first-hand experience to educate you on how to create a product to sell.

They can then help you and your in-house team take your product through this process—especially if this is your first time bringing your own product to market.

You may need an expert in research or a brilliant industrial designer. Undoubtedly, you’ll want a manufacturing partner and prototyping source.

Whatever your product development needs, a service provider like Gembah, that focuses on helping businesses of all sizes create products, is the perfect fit. We have a whole network of organizations and individuals who understand what you are trying to achieve. Experts who are willing to take the time to explain things, to people like you who are eager to listen.

Gembah’s founding principle is the idea that combining the right team of experts with well-established processes is the best way to help any and every entrepreneur, inventor, SMB, and enterprise realize their ideas.

Creating a product is a journey, and we are here to walk side by side with you along the way. Get started today by signing up to the Gembah Marketplace.