TL;DR: The industrial product design process in 2025 bridges your product idea and manufacturing reality. This guide walks through each essential phase—from ideation and prototyping to engineering and production—emphasizing user-centered design, feasibility, and collaboration between designers and engineers.

You’re a product developer with a great idea, but design isn’t your strong suit.

Frustrating, right?

Struggling to turn that idea into a tangible product is common. Without design expertise, the process can feel overwhelming. But there’s a way forward.

Understanding the stages of the product design process can bridge the gap between your vision and reality.

In this article, we’ll break down the steps of product design. You’ll learn how to work with a design team, implement user-centered design, and create products that meet business goals and delight customers.

What Is The Industrial Product Design Process?

According to Industrial Designers Society of America (IDSA), industrial design is the professional practice of designing products, devices, objects, and services used by millions of people around the world every day.

People often misunderstand the industrial design process, believing that because it is “industrial,” it must only apply to raw materials, goods, or services. In fact, every object we come into contact with in our homes, workplaces, or anywhere else in our daily routines are a consequence of industrial design.

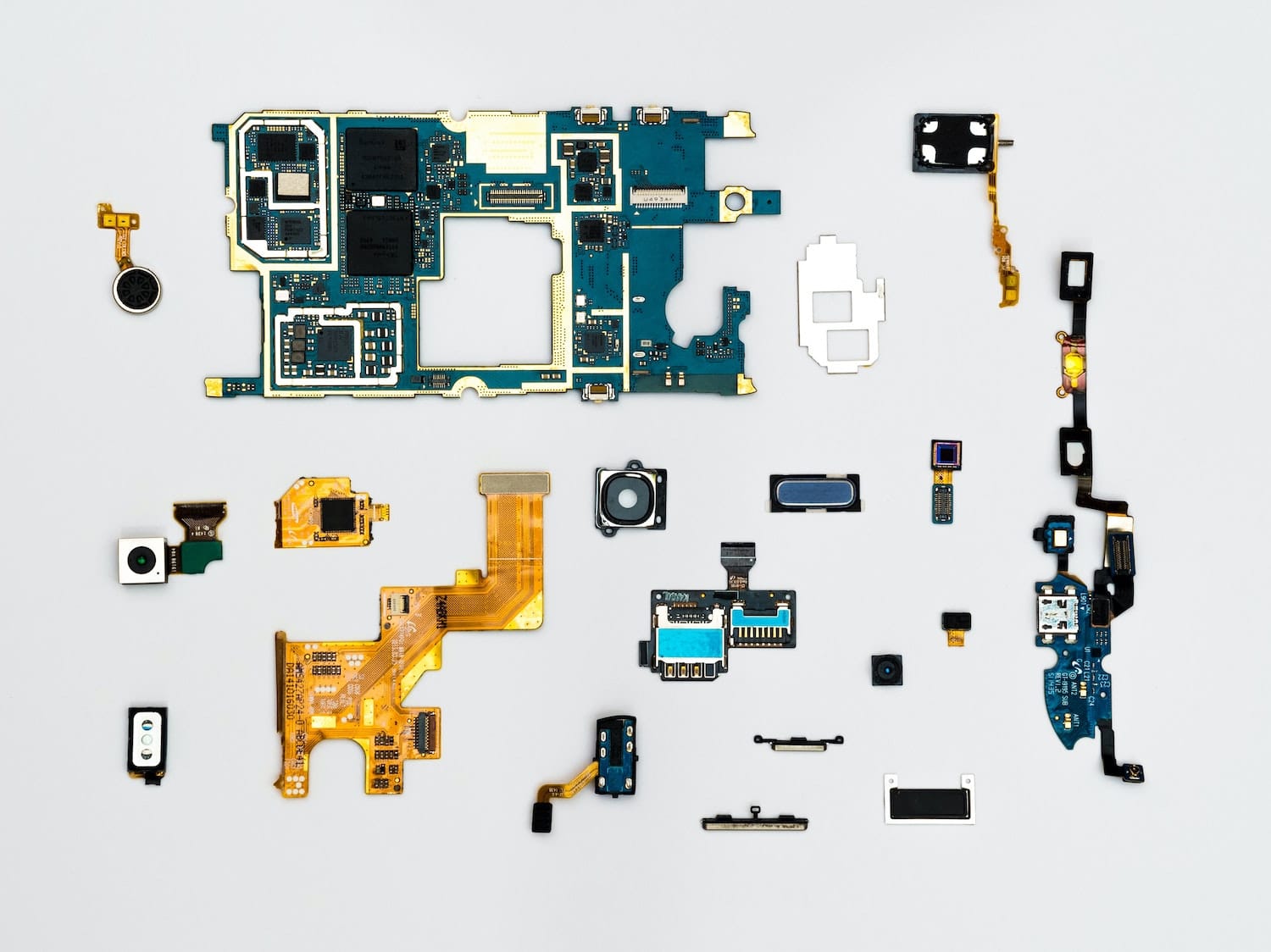

The industrial design process is the most critical element of bringing a product to market. Industrial designers and engineers must consider every aspect of a product, focusing on the product’s manufacturability as much as its appearance and functionality. The ultimate goal of the industrial design process is to finalize a design that has lasting value for the end customer.

The Role of Design Thinking

Good product design begins with the customer in mind. Even a seemingly brilliant product idea is meaningless if an adequate number of consumers fail to see its value. Design thinking is a common process used by industrial designers that puts the customer front and center, solving common problems by either innovating an entirely new product, device, object, or service, or enhancing an existing product. Design thinking is a great approach to capture those needs and let them guide the design process.

Instead of making assumptions about customer desires, design thinking involves prolific research. Product innovators and designers must gather insights by observing customer behavior and interviewing customers to understand their wants, needs, and desires. From there, designers and engineers can sketch out product ideas and build prototypes to bring ideas to life, then present them to a target audience to get feedback and validation.

By focusing on what customers want, empathizing with them to fulfill unmet needs and solve their problems, industrial designers can bring forth better products and continually hone the design process. There is a caveat, however. Design thinking goes beyond creative problem solving to design desirable products; it also equally weighs the product’s viability and feasibility.

Product Viability

During the industrial design process, designers must perform a product viability analysis to determine whether the product idea is practical, can overcome challenges, and requires support services to ensure customer satisfaction. Everything from a product’s size, weight, and fragility to its lifespan, seasonality, price point, and competition plays into product viability.

The product must be able to be manufactured, shipped, and inventoried economically. The more it costs to bring to market, the higher the price point will need to be to cover those costs and provide a decent margin for profitability. If the price point is perceived by customers to be higher than the product’s value, it will not sell well.

Industrial designers are able to use the data gathered during analysis to either scrap the product idea entirely or more commonly, refine the product design to accommodate these variables. By changing the design, materials, and/or factory, designers can transform a product idea from unlikely to perfection.

Product Feasibility

Industrial designers also analyze product feasibility during the design process to establish whether the proposed product is both desirable and in demand. Is the product idea worth pursuing? If the product is an entirely new innovation, demand may not yet be there, simply because consumers are unaware of its possibility. Nevertheless, if the product is designed thoughtfully to solve a problem or fulfill an unmet need, demand will come.

Product feasibility analysis includes focused research, such as concept tests, usability tests, and buying intention surveys. The analysis will reveal whether there is a market for your product, consumer desire for your product as is or if specific modifications would make it more desirable, the price consumers are willing to spend, and if there are competing products that have a loyal following.

Stages of the Product Design Process

The product design process is a structured approach to developing physical products. It involves several stages, each crucial for creating a successful and manufacturable product. Here’s a breakdown of each stage:

Ideation Phase

The ideation phase is all about generating creative ideas for new products. This stage is crucial for exploring possibilities and identifying innovative solutions to meet market needs.

Here’s what to do during the ideation phase:

- Engage in brainstorming sessions to spark creative ideas.

- Conduct idea generation workshops to explore different concepts.

- Sketch preliminary product ideas and concepts.

- Gather initial feedback from stakeholders to refine ideas.

- Identify potential solutions that address market needs.

Concept Development

In the concept development stage, you refine the ideas generated during ideation into viable product concepts. This phase ensures that your ideas are feasible and align with your product vision.

Here’s what to do during the concept development stage:

- Create detailed sketches and 3D modeling of your concepts.

- Conduct initial feasibility studies to test viability.

- Use concept testing to validate ideas.

- Gather feedback from key stakeholders to refine designs.

- Develop innovative concepts that meet market demands.

Prototyping and Testing

The prototyping phase involves creating physical prototypes of your product. This stage is essential for validating your design concepts and making necessary adjustments before final production.

Here’s what to do during the prototyping phase:

- Build functional physical prototypes to test design.

- Conduct usability tests with real users.

- Gather user feedback to identify areas for improvement.

- Make design adjustments based on user experience.

- Repeat product testing until the design meets expectations.

Final Design and Engineering

During the final design and engineering stage, you finalize the product design for manufacturing. This stage focuses on ensuring the design is practical and manufacturable at scale.

Here’s what to do during the final design and engineering stage:

- Develop detailed engineering drawings for production.

- Select appropriate materials for the product.

- Conduct design for manufacturing (DFM) analysis.

- Create production-ready documents for manufacturing.

- Collaborate with product engineers to optimize manufacturability.

Production and Launch

The production phase involves preparing for and executing the product launch. This stage ensures that your product is manufactured efficiently and reaches the market successfully.

Here’s what to do during the production phase:

- Set up the manufacturing process and quality control measures.

- Plan the market launch strategy for the product.

- Conduct final quality assurance checks before launch.

- Coordinate logistics for product distribution.

- Execute the product launch and monitor initial product performance.

By following these stages, you can systematically develop a physical product that is innovative, user-friendly, and manufacturable. Each stage builds on the previous one to create a well-rounded product design process.

User-Centered Design in Physical Products

User-centered design is essential for creating physical products that meet customer needs and expectations. By focusing on the user, you can ensure that your product is both functional and desirable. Here’s how to incorporate user-centered design into your product development process:

User Research

User research is the foundation of user-centered design. It involves understanding the needs, behaviors, and pain points of your target users. This stage is crucial for gathering insights that will inform your design decisions.

User research involves several key activities:

- Conduct user interviews to gather detailed insights.

- Use surveys to collect quantitative data on user needs and preferences.

- Perform observational studies to see how users interact with similar products.

- Create user personas to represent different segments of your target audience.

- Compile research reports to summarize findings and guide the design process.

By thoroughly understanding your users, you can design products that solve real problems and provide value, enhancing the overall user experience and satisfaction.

User Feedback and Testing

User feedback and testing are critical for validating your design concepts. This stage allows you to gather real user insights and make necessary adjustments to improve your product.

Here’s how to gather and use user feedback effectively:

- Conduct usability testing to identify any issues with the product design.

- Organize focus groups to get in-depth feedback from potential users.

- Test prototypes with real users to gather actionable insights.

- Compile user feedback reports to guide design improvements.

- Iterate on the design based on feedback to ensure the product meets user expectations.

User feedback helps you refine your product design, ensuring it is both user-friendly and effective. By continuously testing and iterating, you can create a product that truly resonates with your target audience.

Iterative Design Process

The iterative design process involves continuously improving your product based on user feedback and testing results. This approach ensures that your product evolves to meet user needs and expectations.

Here’s how to implement an iterative design process:

- Make design revisions based on user feedback and testing results.

- Create additional prototypes to test new design changes.

- Conduct further testing to validate the effectiveness of revisions.

- Enhance product designs to improve functionality and user satisfaction.

- Repeat the process until the product is fully optimized for user needs.

An iterative design process allows you to refine your product through multiple rounds of testing and feedback. This ensures that the final product is functional, manufacturable and highly desirable and user-friendly.

The Role of the Product Design Team

The product design team plays a pivotal role in the development of innovative products.

A typical product team working on design in particular will be made up of product designers, product managers, and engineers. This team ensures that every aspect of the product aligns with business goals and user needs. Product designers focus on the aesthetics and functionality of the product, while product managers oversee the process to ensure that the project stays on track and meets strategic objectives.

Collaboration within the product design team is essential for creating a successful product. Regular meetings and brainstorming sessions help integrate different perspectives, fostering a creative process that leads to innovative solutions. The product development team works together to turn ideas into high-fidelity prototypes, which are then tested and refined based on user feedback.

Product managers play a crucial role in coordinating the efforts of the product design team. They ensure that the project remains aligned with business goals and market demands, driving the development of products that not only meet but exceed user expectations. By maintaining clear communication and a shared vision, the product design team can deliver a finished product that stands out in the market. This collaborative approach is key to developing successful products that satisfy both business objectives and user needs.

Designers + Engineering = A Perfect Duo

Industrial designers should never design in a vacuum.

Engineers need to be part of the industrial design process, as they bring a different and valuable perspective to the table. While an industrial designer is focused on designing for the customer, the engineer will ensure that the product is designed for manufacturing.

Design for Manufacturing (DFM) describes the process of engaging engineers to optimize a product or a design element to ensure it can be manufactured as easily, cost-effectively, and efficiently as possible. It is important for designers to work with engineers during the design process and before the tooling and assembly process. The earlier modifications to the design can be made, the less cost and fewer complications and delays.

By designing a product for efficient assembly and with a limited number of standardized materials, for instance, it is possible to reduce costs and bring a product to market faster. While each product varies in its complexity, designers and engineers can work together to simplify the design as much as possible to improve its manufacturability without sacrificing appearance or function.

Examples of Great Industrial Design

The most iconic products begin with a solid industrial design process, one that exquisitely balances form and function to deliver a product people love. By combining innovation and creativity with practicality and prudence, industrial designers and engineers can strike gold, so to speak, developing a product that becomes the standard, a household name, or even legendary.

Take, for instance, the Coca-Cola bottle.

There is nothing like it, and because of its distinct shape and lines, is instantly recognizable, simply by touch. It is easy to hold by any sized hand, is transparent and slender to maximize the view of bubbles rising to the top, and even without a label, immediately signifies a soda. Despite countless competitors over its more than 100 years of existence, Coca-Cola and its iconic bottle design remains, by far, the most valuable soft drink brand in the world.

Other examples of inspiring industrial design come from products that solved a particular problem:

- The “bendy” straw was patented in 1937 after its designer noticed how difficult it was for his young daughter to drink out of a tall glass through a straight straw.

- The ballpoint pen solved the issue of dried-out fountain pens that bleed ink.

- The KitchenAid stand mixer was created as a smaller version of a commercial-grade bakery mixer, suitable for any kitchen to eliminate manual mixing.

All of these innovative designs have changed very little over the decades and are staples in any home or office, proving their lasting desirability, viability, and feasibility.

Let Gembah Help

There is no limit to human imagination and creativity.

By engaging in a proven industrial design process, creators and brands can continually innovate and bring to market products we could never have imagined living without. To do so takes a team of people to look at every aspect of the product, each bringing their own insights and expertise.

Gembah can help you bring those resources together with reliable industrial design and product development processes to ensure your product is designed for the customer and manufacturability.

As design, development, and manufacturing experts, we have curated a network of the best, most specialized professionals from around the globe. Spend less time in trial and error and more time executing validated processes to make your product ideas come to life.