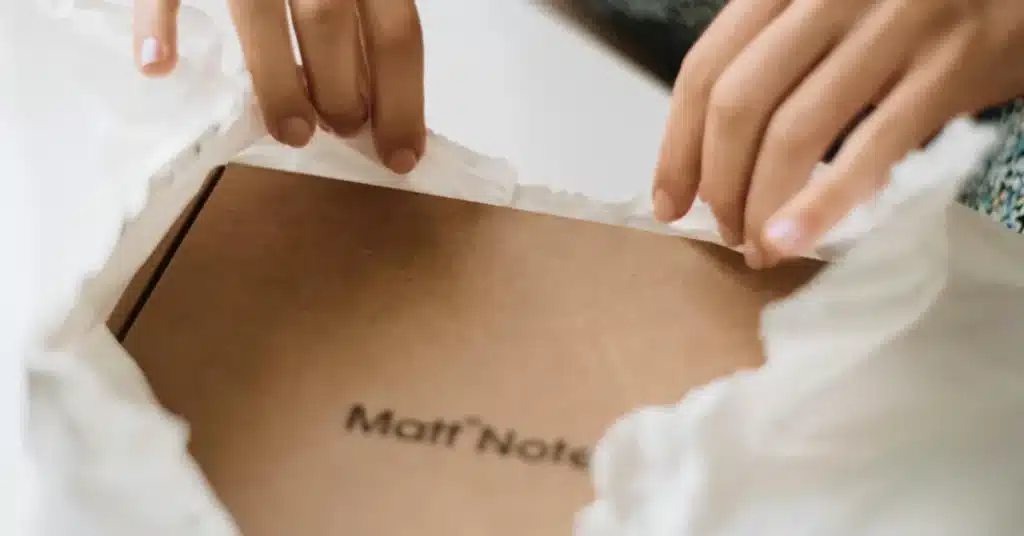

If your product arrives damaged, you lose the sale and the next one. If it arrives in a bloated box, you pay to ship air. If it arrives with no clear setup, reviews stall and returns rise.

This guide shows you how to build an out-of-box experience that protects first and delights second, without overspending. If you want a fast plan that cuts damage, trims shipping cost, and boosts reviews, talk to Gembah about a 30-minute Packaging and Unboxing Review.

TL;DR

Make protection the foundation. Pass a real drop test, then right-size the box so you are not paying extra for empty space. If you sell on Amazon, design packaging that can ship as-is in the network. Keep materials simple and recyclable. Add one clean insert with a QR to a 60-second setup video and a support link. Pilot 25 units, fix what breaks, then lock the spec before you scale.

Key Points

- Protection first. Use a standard parcel drop test to prove your box survives transit.

- Right-size the box. Remove void space so shipping charges stay low and the product arrives tight and clean.

- Amazon ready. When possible, ship in your product’s own box inside the Amazon network to reduce waste and touches.

- Clear, simple inserts. One card, short setup video, obvious support channel, neutral review ask.

- Good, Better, Best budgets.

- Good: plain shipper, one-color logo, folded insert.

- Better: custom mailer, simple insert tray, one inside print panel.

- Best: easy-open tear strip, snug insert, minimal branded wrap.

- Pilot, then freeze. Run a small pilot, fix failure points, then lock box size, materials, and print to avoid retests and waste.

Start with protection, then add delight

Your packaging strategy should follow a simple hierarchy: protection trumps presentation every time. Before you invest in foil stamping or custom inserts, ensure your product survives the journey. Industry studies reveal that parcels experience an average of 17 drops during typical delivery routes, with drop heights reaching 48 inches.

This protection-first approach aligns with what packaging industry leaders emphasize. As Sealed Air Corporation experts state: Sustainability demands innovations that minimize environmental impact while maintaining performance, safety, and shelf life. Their research underscores how effective protection forms the foundation for any successful unboxing experience.

This approach aligns with what we see in successful product development. Multi-stage quality assurance processes, including pre-production material testing and final product evaluations, prevent defects that could ruin even the most beautiful unboxing experience. When your product arrives damaged, no amount of branded tissue paper will save the customer relationship.

Method’s cleaning products demonstrate this balance perfectly. Their 2023-2025 packaging redesign introduced bottles using recycled plastics, ergonomic designs, bright colors, and clear labeling to blend visual appeal with function and sustainability. The result was improved customer satisfaction scores and notable increases in customer loyalty through packaging-led brand differentiation.

Once protection is secured, you can layer in delightful touches that create emotional connection. Think clean presentation, intuitive organization, and subtle design elements that reinforce your brand identity without breaking the bank.

Pass a real lab drop test

Your packaging needs to survive real-world conditions, not just look good in mockups. With improper stacking and compression causing roughly 40% of package damage, your packaging must withstand more than gentle handling.

Conduct actual drop tests from various heights and angles. Test your packaging when it’s fully loaded, partially filled, and in different orientations. Frequent on-site assessments help verify that manufacturing partners maintain these standards consistently, ensuring every customer receives an intact product.

Consider the materials that offer the best protection-to-cost ratio. Corrugated cardboard with proper fluting, strategically placed foam inserts, and secure closure systems often provide excellent protection without premium pricing.

Selling on Amazon? Use “Ships in Product Packaging”

Amazon’s “Ships in Product Packaging” program can slash your fulfillment costs while improving sustainability. However, this requires packaging robust enough to serve as both product packaging and shipping container. Your out-of-box experience design must account for Amazon’s handling requirements and customer expectations.

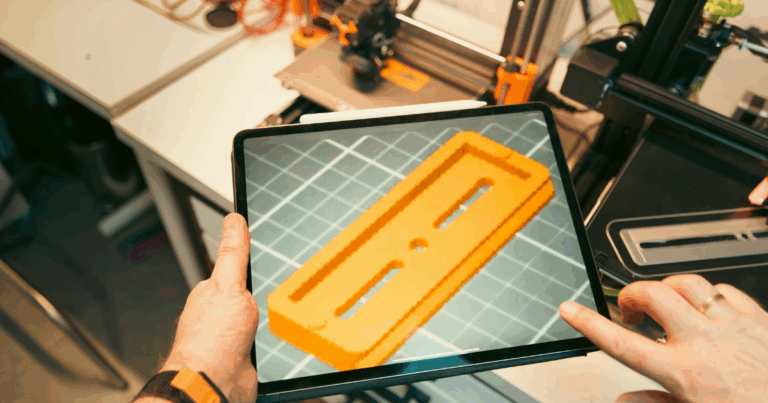

Design packaging that communicates your brand even when it arrives without an outer Amazon box. This means investing in durable external graphics, secure closures, and clear product identification. The oobe commands from customers become even more important here—your packaging needs to guide them through setup or usage without additional materials that might be lost in transit.

2025 Cost Changes You Must Design Around

The packaging landscape is shifting rapidly, and smart brands are already adapting their designs. Industry authorities warn that by 2025, 90% of public sustainable packaging commitments won’t be met due to reliance on plastics and single-use packaging. New regulations and industry practices are reshaping cost structures across the supply chain, making it crucial to understand these changes before they impact your bottom line.

Rounding of box size

Shipping carriers are implementing stricter dimensional weight calculations and rounding practices. This means a box that’s 12.1 inches might be charged as 13 inches, significantly impacting your shipping costs. Design your packaging dimensions to align with these rounding thresholds.

Work backwards from carrier requirements to optimize your packaging size. Sometimes reducing a box dimension by half an inch can drop you into a lower pricing tier, saving significant money over thousands of shipments. This optimization requires close collaboration between your design team and fulfillment partners.

New EU packaging rules

The European Union’s new Packaging and Packaging Waste Regulation introduces sweeping changes starting in 2025. All packaging must be recyclable in an “economically viable way” by 2030, with minimum recycled content requirements for plastic packaging ranging from 30-65% depending on type.

More immediately, the €2 fee for every shipment to the EU starting February 2025 affects all parcels regardless of value. Additionally, carrier ETS surcharges could nearly double compared to 2024 as companies must purchase emission allowances covering 70% of their emissions.

Leading packaging companies are responding to these regulatory shifts. Amcor plc’s leadership emphasizes that high-barrier, lightweight, and compostable materials, coupled with recycling partnerships, position us to achieve all packaging recyclable or reusable by 2030. They acknowledge that technical hurdles have caused leading brands to publicly reset their packaging goals, refocusing efforts to balance ambition with achievable outcomes.

These changes demand proactive material selection and design modifications. Choose materials that meet recyclability requirements while maintaining protection standards. Consider regional packaging strategies to minimize EU-specific compliance costs.

Good, Better, Best: Unboxing on a Budget

Creating memorable unboxing experiences doesn’t require unlimited budgets. Recent case studies demonstrate significant returns across all price tiers. Pringles’ transition to 90% paper-based, recyclable tubes maintained their distinctive tube shape while boosting brand loyalty among eco-conscious consumers. Meanwhile, Liquid Death’s bold, unconventional can designs fostered a strong community and drove high retention rates through packaging-led social media virality.

By understanding cost tiers and their impact, you can strategically invest in elements that deliver the highest return on emotional investment.

Good, under $0.50 per unit

At this price point, focus on the fundamentals executed flawlessly. Clean organization, protective packaging, and basic branding can create positive impressions without premium costs. One electronics brand maintained NPS scores and saw 12% improvement in fulfillment time by simplifying their packing process while including branded inserts.

Use standard corrugated boxes with simple branded stickers or stamps. Include a basic thank-you note or care instruction card—printed materials cost pennies but add personal touch. Organize contents neatly with minimal protective materials like paper fill or basic foam inserts.

The key is consistency and attention to detail. Every element should feel intentional, even if simple. Clean edges, aligned text, and organized presentation communicate quality without requiring expensive materials.

Better, $0.50 to $2.00

This tier allows for enhanced materials and custom elements that create stronger brand recognition. Consider custom printed boxes, branded tissue paper, or designed inserts that provide functional value beyond protection. One beauty brand achieved a 14% increase in repeat purchases and 20% uptick in social media shares while keeping unboxing costs below $0.50 through streamlined SKUs and standardized packing lines.

Invest in one standout element rather than multiple mediocre touches. Custom printed tape, embossed logos, or unique structural designs can create memorable moments. Add functional inserts like quick-start guides, QR codes linking to setup videos, or care instructions that support customer success.

Consider sustainable upgrades that communicate values while adding perceived value. Recycled materials, plantable seed paper, or compostable packing materials resonate with environmentally conscious customers. Sonoco Products Company’s approach exemplifies this strategy—their EnviroSense product line advances eco-conscious design, targeting waste reduction and enhanced recyclability without compromising performance or cost-efficiency.

Best, $2.00 to $5.00

Premium unboxing experiences in this range can include multiple custom elements, high-quality materials, and interactive features. Think magnetic closure boxes, custom molded inserts, premium paper stocks, or small branded accessories.

Skims demonstrates this approach effectively. Their distinctive, minimalist packaging designed for easy use, unboxing shareability, and reduced waste achieved high net promoter scores and increased social media mentions. The enhanced emotional connection and virality contributed to improved repeat purchase rates and stronger ROI.

At this level, every touchpoint should reinforce your brand story. Custom typography, consistent color palettes, and tactile elements like soft-touch coatings or textured papers create sensory experiences that customers remember and share.

Include elements that extend the relationship beyond unboxing. Branded accessories, discount codes for future purchases, or collectible items encourage retention and word-of-mouth marketing.

Inserts That Drive Reviews

Strategic package inserts can encourage positive reviews, but they must be designed thoughtfully to avoid appearing pushy or violating platform policies. The importance of reviews cannot be overstated—products with 5 reviews have a 270% higher probability of purchase than those without, and displaying customer reviews can boost conversion rates by up to 270%.

The challenge lies in generating authentic feedback while maintaining compliance. Research shows that 88-91% of consumers trust online reviews as much as personal recommendations, but 95% suspect manipulation if there are no negative reviews. This creates a delicate balance between encouraging feedback and maintaining authenticity.

Focus on making the review process effortless rather than incentivized. One review can yield a 10% conversion increase, scaling up to 37% or more with 100 reviews. Even negative reviews can increase conversion by up to 85% by building trust and signaling authenticity.

What to include

Start with genuine gratitude. A brief, personalized thank-you note acknowledges the customer’s choice and sets a positive tone. Include clear but unobtrusive directions to review platforms using QR codes or simple URLs that eliminate friction.

Since 70% of shoppers require at least 5 good reviews before purchasing, steady review solicitation through inserts becomes essential for new or low-volume products. However, maintain compliance by using neutral language like “We’d love to hear your feedback—please review your purchase online” rather than requesting specific star ratings.

Provide customer support contact information prominently. This demonstrates confidence in your product and gives customers an alternative to negative public reviews when issues arise. Include setup tips, care instructions, or usage suggestions that help ensure positive product experiences.

Keep messaging platform-compliant by focusing on honest feedback rather than specifically positive reviews. Avoid any incentive or messaging that could be construed as review gating or manipulation.

Simple build plan

Successful packaging rollouts require structured approaches that minimize risk while maximizing learning. Start small, gather data, and scale systematically.

Pilot first

Run small-scale pilots that closely replicate full production conditions. Test actual materials, manufacturing processes, and shipping scenarios to identify potential issues before large-scale rollout. Typical pilot timelines run 2-4 weeks, focusing on quality yields and operational bottleneck identification.

Gather feedback from multiple stakeholders during pilots. Include customer reactions, fulfillment team input, and retailer requirements. This comprehensive feedback prevents costly corrections later in the process.

Use pilots to validate cost assumptions and supply chain capabilities. Test your supplier’s ability to maintain quality standards and delivery schedules under production pressure.

Lock the spec

After incorporating pilot feedback, finalize all specifications to ensure consistent production. Locked specs facilitate accurate cost forecasting and reliable fulfillment across all channels. Document everything from material specifications to assembly instructions, ensuring reproducible quality.

Work with experienced designers and manufacturing partners who understand both creative requirements and production realities. This collaboration ensures your vision translates effectively to scalable manufacturing processes.

Consider splitting production between multiple suppliers to reduce risk and maintain competitive pricing. This approach also provides backup options if quality or delivery issues arise.

Create Profitable Products Faster

Our Process Takes Products From Market Research to Production -> FAST

Conclusion

Great unboxing is not about fancy paper. It is about fewer damages, lower shipping costs, and faster reviews. That is the path to repeat orders and higher lifetime value.

If you want a packaging spec that protects your margins and makes customers happy on the first open, book a Packaging and Unboxing Review with Gembah. We will map your test plan, dial in box size, and build inserts that lift reviews without lifting your budget.