Launching a new product can be intimidating.

You’ll have a ton of questions running through your mind like:

- “How do I do proper market market research?”

- “What’s my budget to get a good product design ready?”

- “How should I position my product in the market?”

- “How am I going to actually manufacture the product?”

The list goes on, but one of the most common we hear often is this:

“How am I going to actually manufacture the product?”

In this guide, we’re going to cover two primary methods you can use:

White labeling and private labeling.

We’ll take a detailed look at both white labeling and private labeling strategies, including the key differences between the two and the pros and cons of each, then help you decide which path is best for you.

Let’s do it.

TL;DR: The difference between white label & private label product manufacturing

- White label products are mass-produced and sold to multiple retailers, while private label products are produced exclusively for a single retailer.

- With white label products, the manufacturer dictates small variations like size and color, whereas with private label products, the retailer has full control over the design and specifications.

- Private label products allow for more customization and branding, making them better for creating a specific brand message.

- Private label manufacturing can take longer and be more expensive due to the customization process, while white label products are often manufactured in advance or at short notice.

- White label manufacturing leads to a less defensible type of products, while private labeling lets you product exclusive products that are difficult to replicate

White label products

White label products are produced without any branding or company logos. These often generic products are then branded and sold by another company. Typically, white label manufacturer sell the same product to multiple companies.

For example, consider a manufacturer selling luggage bags as a white label product.

The manufacturer could sell this bag in large quantities to a large corporation, which then sells it to an end consumer like you and me under its brand name. However, the same manufacturer could also choose to create its own brand and sell it directly to the end consumer at a higher price point. Or the manufacturer could choose to sell the bag to multiple large corporations.

In any case, the product reaching the end consumer is largely identical, and the only differentiation is the branding and packaging of the product.

So, why do certain companies use white labeling?

Benefits of white label products

White label products offer a multitude of benefits for businesses looking to expand their reach, de-risk their product launches, and more.

1. Speed up product launches

With a white label strategy, you don’t need to invest any capital or resources in research and development. You have a product ready to be sold and rely on your branding and marketing efforts to sell it.

2. Minimize risk

When you purchase a white label product, you buy a product that has been tried and tested in the market. You buy your products from companies renowned for making a particular product while you stick to what you do best: selling.

3. Explore new product avenues

Feeling pressure to introduce a new product into the market but unsure about what to sell? It may not be the best strategy, but white labeling can help by allowing you to choose from a wide variety of products to sell.

Drawbacks of white labeling

A white label strategy can work great for giant corporations and national brands that can purchase white label products, brand and package them, then sell them by means of their easily-recognizable brand name and sophisticated marketing strategies.

However, if you’re an SMB or Fortune 5000 company, you may want to consider these drawbacks before adopting a white label strategy.

1. Zero defensibility

When you rebrand and sell white label products, there’s a genuine possibility that your competitors might be selling the same product. And with nothing unique about your product compared to your competitors, it’s only a matter of time before they begin eating into your market share.

2. Inconsistent quality

Your supplier of white label products may not have good quality control measures in place. Hence, customers might have different experiences every time they buy your product. Moreover, what do customers see every time they receive a poor quality product? Your precious brand logo.

3. Less production process control

With white label products, you can’t control or specify how your product needs to be manufactured. You can only control your product’s marketing, distribution, and sales.

For a business to have long-term viability, it is crucial to have differentiated products. You need to have trade secrets that only you know. And that is where private label products come in.

Private label products

Private label products are products that a company produces to sell exclusively under its brand name.

While the company may still get the product manufactured by an external private label manufacturer, it controls product specifications, quality standards, and everything else.

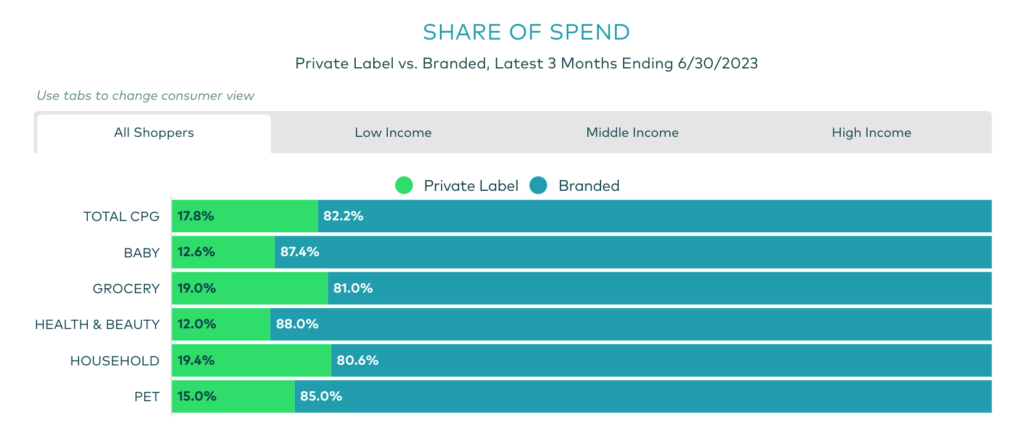

Unlike a white label manufacturer selling the same generic items like luggage bags to multiple retailers, a company that develops luggage bags with unique specifications to be sold exclusively to the end consumer would be an example of its private label counterpart.In fact, roughly 21% of grocery, household, and health & beauty units sold across all income levels are private label.

Benefits of private label products

Private labeling can bring plenty of benefits for brands. Even when working with a third-party manufacturer, you’re still able to maintain a lot of control over the overall process.

And there are more benefits beyond just the manufacturing process control:

1. Competitive edge

Private label products are unique products in the market that only your brand can sell. This enables you to stand out from your competitors. Moreover, with greater control over production, you can ensure that your customers get a consistent experience every time they buy your product. Ultimately, this translates to increased brand loyalty.

2. Easy customization

You know your customers’ needs better than anyone else, right? After launching a product, it’s easier and quicker to make improvements on your products if you have control over production. Subsequently, you are in a better position to launch the next version of your product.

3. Better pricing control

As we’ve already seen above, private label products are differentiated products that help you stand out from the competition. As a result, you can charge higher prices for your product, which in turn leads to higher margins.

4. Improved profit margins

Private labeling can produce significantly greater margins compared to traditional manufacturing where a retailer does all of the heavy lifting themselves.

In fact, retailers often see gross margins on private labels that are 25–30% higher than those on manufacturer brands, largely due to lower cost management efficiencies.

Challenges with private labeling

Difficulties may occur when using private labeling, even though it has many benefits. Brands can decide how they want their products to look and be branded, but there are problems that may come up.

These challenges can affect different parts of the private label process, so it’s important to think carefully and make plans to solve them.

1. Access to high-quality products & manufacturers

Access is often a major challenge for product developers and entrepreneurs looking to create private label products. Finding reliable manufacturers who can produce high-quality products that meet your specifications can be time-consuming and costly.

Platforms like Gembah can help though. Entrepreneurs can gain access to a vast network of vetted manufacturers who specialize in private label production. This can streamline the product development process and ensure that the final product meets the desired quality standards.

2. Thoroughly research & understanding your target market

The other primary challenge with private labeling is truly understanding what the target market you’re planning to chase is looking for. This means looking at what they like, what they need, and how they like to buy things.

Far too often this step gets skipped and brands sink a ton of capital into private label products that never had a shot at succeeding in the first place.

How to decide which path is best for you

If you’re developing products on behalf of a massive corporation or with a globally-known brand name to lean on, white labeling may be best.

For the overwhelming majority of brands that want to produce high-quality products, our advice is this:

Private label manufacturing is best.

If you want to retain a competitive advantage, build a long-term brand, and hit your business goals—selling products manufactured by private label brands is the way to go. Even more so if you plan to manufacture your products too in the future.

This edge is validated by consumer spending as well.As of mid-2023, private label products accounted for 17.8% of total CPG spending, with household products even higher at 19.4%.

So what stops a business from building private label products?

And how can you get started?

How to find & produce private label products with the Gembah platform

Developing a private label product from scratch can be pretty daunting. You might not be experienced in market research to figure out your target audience or you may face difficulties in hiring the right people to get your product design ready.

Gembah is the first global marketplace for product development that empowers SMBs and Fortune 5000 companies to bring their product vision to reality.

Gembah makes creating a private label product easier for you by:

- Being a one-stop-shop solution to help you at each stage of the product development process, from research to supply chain and logistics.

- Granting you access to a vast vetted network of product designers, manufacturers, and logistic partners to build your product efficiently and quickly.

Explore the Gembah marketplace now to find a wide range of private label manufacturers for all types of products—from physical products like personal care products and more.

Get started with Gembah today.