If you have started searching for a partner to help you take your product idea to market, you have probably heard the terms industrial design and product design tossed about a lot. And, you may be a little confused about what the difference is or even if there is a difference. You are not crazy. The difference can seem small, and you may be sensing that one type of design is a subset of the other.

It can be confusing for someone who has never gone through the product development process before. However, understanding that difference can determine the success and failure of new products, so it is vital to know how those differences can impact your effort. This article aims to explain the two terms, what they share, and why it matters to any entrepreneur who is trying to develop a product.

Product Development, Product Design, and Industrial Design

Before we dive into the details, let’s review how to create a product by scanning the eight steps most products go through in order to make a product:

- Document what your potential customer wants

- Research the market

- Design your product

- Engineer a manufacturable new product that works

- Build a prototype, test, and iterate

- Find your manufacturing partners

- Plan production

- Manufacture your product

Steps three and four are where product and industrial design occur, although they take input from and provide output to the other steps. And that output is what sets the two apart.

From a high level, industrial design defines your customer’s experience with your product, how it looks and behaves. Product design starts with and includes industrial design and then adds all of the details defining everything needed to manufacture your product.

As an example, let’s say you are bringing a new coffee machine to the market, and your device has buttons to turn it on and control the brew. In industrial design, your team will define what those buttons look like, what it feels like to press them, and what happens when you press them. Product design starts with the industrial design and then defines the detailed geometry of the buttons, the mechanism inside, the suppliers for the material and components, the precise dimensions, how to inspect it, and every other detail needed to define the product for manufacturing.

What Is Industrial Design?

This is a little broader than most people define it, which is what you expect from the organization that represents people doing industrial design — they don’t want to box themselves in.

For most people in product development, industrial design focuses on the physical appearance, functionality, usability, and manufacturability of mass-produced consumer products. It is the process of defining the user experience for the product and specifically what it looks like and what it does. People doing industrial design also often have good graphic design skills so they can convey their ideas to their customers, especially in the conceptual phase.

Some History

Artists had always used their creativity to help design products made by artisans destined for the wealthy aristocracy. But with mass production came the mass market, and appealing to the aesthetic and functional needs of the customer became a way to differentiate your products in the market.

The practice of using people trained in art, architecture, interior design, ergonomics, and creative processes to make sure products were visually appealing and functioned well became popular after the First World War, and exploded after the end of the Second World War. At some point in the 1950s, they started calling it industrial design.

In the 21st century, companies like Apple utilized industrial design to revolutionize consumer electronics and computers, and other industries soon followed. Consumers began to expect products to be designed well where the entire experience, from purchase through support, was positive. Packaging, advertising, and even the retail or online storefront included the aesthetic (the look and feel) of the product itself. Digital products like websites and software also incorporated the tenants of industrial design in shaping their user experience, especially the user interface for software.

Aesthetics and Emotion

Often, an even more important aspect of a design is the emotional experience a customer has with a product. And good industrial designers will balance the aesthetic and the emotional with manufacturing needs.

A great way to summarize industrial design is to think of the output of this process as defining the customer’s experience from both an emotional and utilitarian point of view. This is usually in the form of sketches or a conceptual 3D CAD model along with a document listing product features and behavior.

What Is Product Design?

The definition for a product is “something that is made or grown to be sold or used.” Design’s definition is “to plan and make decisions about (something that is being built or created).”

Therefore product design is: To plan and make decisions about something that is made or grown to be sold or used.

If you think about that, you can realize that industrial design — planning and making decisions about how a product interacts with the end-user — is a part of product design. In most cases, industrial design is where product design starts.

But a definition of how a product looks and acts is only that first step. Now engineers of various types, usually mechanical engineers for physical products, need to figure out all the details. Some people call this part of product development engineering design and design for manufacturing.

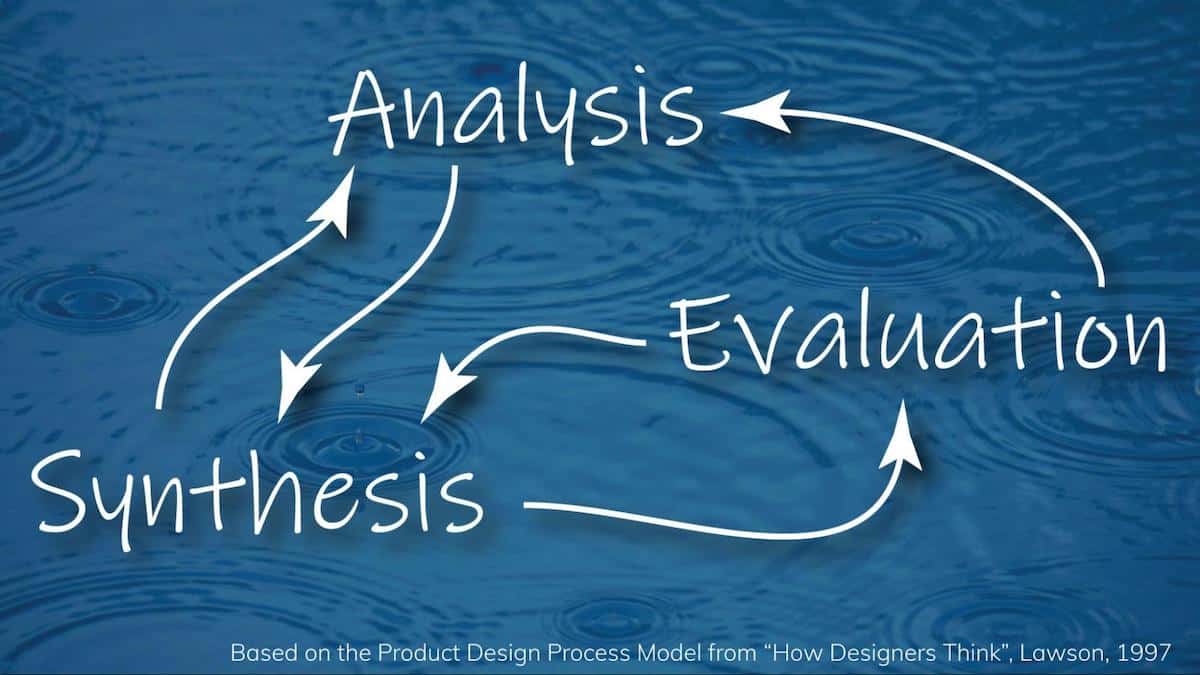

Product design follows a process model, defined by Lawson in his book “How Designers Think,” and involves three iterative steps:

- Synthesis: In this step, the team uses creative problem solving to develop solutions. Evaluation: Finally, the team evaluates how well the solutions they came up with work, if they meet the needs found in the analysis stage, and if the ideas developed in the synthesis stage work.

This process is repeated until a complete definition of the product is worked out and it is ready for manufacturing.

Which brings up another important aspect of product design — figuring out how to manufacture the product. As mentioned, a good industrial designer will include manufacturing considerations in their designs. But it is up to the full product design process to make sure all manufacturing processes are considered, components can be sourced, the parts can be made, and the whole thing can be put together. The product design engineers will work with manufacturing engineers during the design process and often well into production. Other members of the product development team give input to product design after completing the industrial design.

A great way to summarize product design is to think of the output of this process as the 3D CAD model, drawings, specifications, and a Bill of Material (BOM) for the product. Everything the manufacturer needs to know to make the product is in the output from product design.

What Do Industrial Design and Product Design Share?

The number one aspect of product development that both industrial design and product design share is defining and meeting the customer’s needs — making a product that has value and that consumers are willing to pay for. Both aspects of design require researching what the market wants and getting it into the product. Research is a critical input to both.

Another aspect of the design process that they share is prototyping. The only difference is what the goal is from a prototype. An industrial designer may want to create a detailed color 3D model of a part in the product to hold it in their hand, look at it, and understand what the user experience will be with the actual product. After industrial design, as product design continues through engineering and design for manufacturing, prototypes can be 3D printed from plain white plastic and put into the assembly to make sure it fits and behaves like it is supposed to. At each step, user interaction can be measured and feedback from stakeholders can be gathered.

Most importantly, both processes are interactive and take input from other members of the product development team. This iterative process can be the most frustrating aspect of both product and industrial design, but it turns good ideas into great products.

Industrial Design vs. Product Design: When It Matters

First, you can make the wrong choice for your product development partner if you only hire a firm that does industrial design. Yes, industrial design is critical, and the results are what your customers experience. However, there is so much more to product design than industrial design — the full product design is where the details are defined.

Second, you need to know where your product is in the product development process so you can provide the right type of critical input. As part of industrial design you will be shown sketches of what the product looks like, down to what color things should be. Your job at this point is to think like the industrial designer and make decisions based on the customer experience. How will those colors make them feel? Do they reflect your brand? How important is the click the customer feels when they press that brew button? Is the product meeting user needs?

Once you are past the industrial design and into completing product design, it is time for you to focus on the bigger picture and make decisions that take manufacturing, marketing, supply chain, time to market, and cost into account without forgetting that customer experience.

The most important thing you can do is pick a partner that understands the difference between industrial design and product design and deliver on both — a partner like Gembah. Our purpose in life is to provide entrepreneurs who have great product concepts with a complete solution that includes research, product design (including industrial design) sourcing, product management, logistics and compliance, and supply chain evaluation.

Get started by telling us what type of product we can help you make.