Whether you’re figuring out how to make a product from scratch or how to build a product for a specific market, the process remains the same. Successful product creation requires a clear path from a “new product” idea to the manufacturing line.

TL;DR:

How to create a product is a process that follows eight key steps: identify your customer’s needs, research the market, design and engineer your concept, prototype, find a manufacturing partner, and plan production. This guide explains each phase so you can move from idea to successful launch—faster and smarter.

You have an idea. You’ve identified a market.

Now it’s time to create your new product.

You can see where you want to go, but unless you have done it before, the journey from your idea to a warehouse full of things to sell could be a bit of a mystery.

Don’t worry—the process of how to create a product is well understood, and plenty of experts can help. This article will share the most important steps and advise entrepreneurs leading a consumer product startup.

What Makes a Product Successful in Today’s Market

As the entrepreneur driving a product idea, this is your number one priority.

The technical and business people you work with along the way will come up with great ideas. They will get deep into the weeds, trying to solve real problems that pop up along the way. Your job is to watch and make sure that the team expends energy on activities that result in features that address market needs. This whole process is called product/market fit.

There is a quote that marketing people use that everyone should understand before they build a product. Harvard Business School marketing professor Theodore Levitt said, “People don’t want to buy a quarter-inch drill. They want a quarter-inch hole!”

A successful product allows the customer to do what they want to do. This approach is called human-centered design, and it takes things a step further than identifying the product/market fit.

The 8-Step Process for Creating a Product in 2025

The entire product creation process can be boiled down to eight primary steps.

1. Document what your potential customer wants

No one wins if you are the only one who knows what the customer wants. Someone has to write it down so everyone is on the same page. This step is not about documenting features. It is about capturing your product’s benefits. Don’t worry about the “how”—that comes later.

Your product specification, the output of this step, will also be used as a roadmap to develop your marketing strategy and set your marketing plan. Focus on the “what” and the “why.” As you complete the next step and work your way through the product development process and even into manufacturing, update your product specifications.

2. Research your target market and your target customers

The next step requires you to stop, look, and listen.

The worst place to learn about your market, especially your competition, is when you already have a warehouse full of boxes. You may have heard the term R&D applied to product development. It stands for research and development. The research part is first because you need to know about your market, competition, and past successes in the early stages of your product development process. Until you do market research, you are only making assumptions.

As with every step in this process, experts, often freelancers, specialize in conducting research and presenting the results. Some of the common tactics used in product development research are:

- Customer profiles: Define your target audience and what they prioritize.

- Consumer interviews: Talk to people in your target demographic, explain the benefits of your product concept, and listen to what they think.

- Competitive analysis: Find products that do what you plan to do and document their strengths and weaknesses.

- Comparison analysis: Determine what customers can do instead of using your product. Then capture the advantages and disadvantages of those alternatives.

Repeat this step when you have a prototype and capture the output from this effort in your product specification.

Testing Your Product Idea Early

In the early stages of product design, gathering customer feedback is crucial for validating your marketing strategy. Before moving into mass production, consider developing a minimum viable product to test with your target customers. This approach helps you understand real-life ownership challenges and refine your product management process. Getting positive feedback about your key selling points early on can save significant resources and time. Many successful entrepreneurs start developing prototypes they can test with potential customers even before finalizing their product launch plans, allowing them to iterate based on actual user experiences.

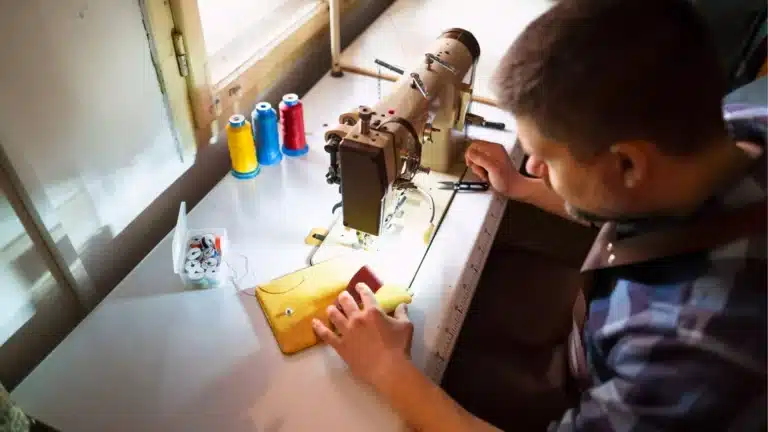

3. Design your product

Now it is time to define the “how” for your product. This is where your napkin sketch, some new disruptive technology, or the idea you had in the shower turns into something tangible — you start to develop the features of your product. Other terms for the design step are conceptual design, preliminary design, product design, or industrial design.

The best way to start this process is with ideation, an interactive process where you create quick sketches of both what the product looks like and what it does. A good product, and especially a great product, balances look and feel with functionality. When done correctly, aesthetics deliver functionality.

Compare the different concepts against your customer needs and what you learned in research to find the best design. Brainstorm new ideas, continue to modify that design, and iterate at a high level until your product has what it needs and nothing more.

4. Engineer a manufacturable new product that works

Up to this point, your product development team has been defining things at a higher level and not worrying about details—now it is time to worry about details. This step aims to fully define a manufacturable product with all of the desired features and functions. Some people call this step detailed design. It’s also a great place to apply the principles of lean product development.

The output from the engineering step is a complete definition of your product. The shape and size, components, how things fit together, how they are held together, materials, colors, surface finishes, software, user interface, buttons, sounds it makes … the list goes on and on. A lot of decisions need to be made and the most important thing you need to do is make sure that all of those decisions drive towards the value your customers will be paying for.

Most entrepreneurs underestimate the effort required in engineering. But if you don’t take the time to do it right, you won’t end up manufacturing the product you designed. Worse, you may end up defining a product that can’t be made at all.

5. Find your manufacturing partners

Around the time you start engineering, you also need to search for your new best friends, your manufacturing partners. This company, or companies, will take your design and turn it into something you can sell. You need to find them at this point because they need to help drive the design for manufacturing.

If you don’t know their capabilities and various ballpark costs, you will be making assumptions that could be wrong. Fixing those mistakes when you are trying to ramp up production is the most expensive way to go.

6. Build a product prototype, test, and iterate

Your team should start building prototypes when your product definition is solid enough.

Having a physical product model will help answer questions about the design and take your market research to the next level. You can see how it looks, test its performance, get opinions from potential customers, and explore different solutions.

A prototype can be as simple as a cardboard cutout, a digital mockup, a physical model made with easily shaped materials or 3D printing, or a working prototype made by your manufacturing partner. This iterative process is part of working with your manufacturing partner and should be built into your team’s product development process.

7. Plan the production of your new product

The production planning step starts in the final stages of the engineering and prototyping iteration process.

Production planners, manufacturing engineers, quality engineers, and supply chain people take the complete product definition and turn it into a supply chain map, production plan, and quality system. All off-the-shelf components are sourced, custom tools like injection molds are designed and ordered, each step in manufacturing is laid out in detail, and an inspection and tracking system is put into place to ensure quality.

8. Manufacture your new product

After completing these previous steps, it’s finally time to start manufacturing. But your job and the job of your product development team is not over. Production, when done right, is also an iterative and interactive process.

Use an approach like lean manufacturing to continuously improve and remove waste from every link in your supply chain and every step in your production plan. Quality should be measured and tracked to drive the right improvements. As the person driving this machine, your primary job is to hold everyone accountable for meeting your cost, schedule, and quality goals.

A few variables to consider when creating a new product from scratch

Beyond the end-to-end process itself, keep the following five things in mind as you create your new product.

You have to actually sell what you’re creating

It would be a much better world if products could sell themselves. And a fantastic product is certainly easier to sell. However, you still have to let people know about it and then facilitate their purchase.

There are many avenues for getting your product into the hands of your customers. While you are doing your market research, also explore the best way to market and sell your product. Develop a go-to-market strategy that includes a marketing plan, what your sales and distribution look like, and how customers will buy from you.

Ask yourself how you will use social media, e-commerce, and digital marketing to reach your target market.

Build branding into the design from the start

You should incorporate your company and product branding into your design from the beginning.

Branding can drive a design, and a design can drive branding. The aesthetics of your product or the user experience as your customer interacts with the product may reflect branding. It is undoubtedly in your packaging.

Branding is about customer experience and emotion as much as product fit, form, and function. Take time to look at iconic brands like Apple, Nike, and Gucci and consider how their designs reflect their brand.

Protect your intellectual property

The better your product, the more people will want to copy it.

So, protecting your intellectual property (IP) through patents, trademarks, and trade secrets is an essential part of bringing your idea to market. Don’t forget that your manufacturing processes and design may also contain IP. As a business owner, you are also trying to build assets for your company, and IP can be very valuable to investors and other stakeholders.

Map out all of the logistics

You need to get your product from where it is made to the customer, with stops along the way. Logistics is about shipping, warehousing, and delivering the product where it needs to be when it needs to be there. You should work on logistics in parallel with your production planning. The goal of logistics is reliability and flexibility.

Don’t neglect customer support and plan for repairs

Once your product is in the hands of your customers, they are going to have questions. And, no matter how good your design is, some of your products will need repair or replacement. Plan this important part of your business and scale it as your sales increase.

Find the right partners to help create your new product

It may be an expert in research or a brilliant industrial designer. It is undoubtedly your manufacturing partner and most likely your prototyping source. You may count on freelancers or an established service provider like Gembah that focuses on nothing but helping small businesses create products.

Find organizations and individuals who understand what you are trying to achieve. They should be willing to take the time to explain things, and you, in turn, should be eager to listen.

Gembah’s founding principle is the idea that bringing together the right team of experts with well-established processes is the best way to help entrepreneurs realize their ideas. Creating a product is a journey, and we are here to walk side by side with you along the way.

Frequently Asked Questions About Creating a Product

How long does it usually take to go from idea to first shipment?

Most first-time founders should plan on 9–18 months from initial idea to a real shipment, depending on:

- How complex the product is

- How many times you need to iterate on prototypes

- How fast you can make decisions and give feedback

- How long tooling and manufacturing setup take

Simple products with few parts can land on the shorter end. Anything electronic, safety-critical, or highly regulated usually takes longer.

How much does it cost to create a new physical product?

There’s no single number, but most consumer product startups should plan for at least five figures before the first full production run. Your budget usually goes into:

- Research and design (industrial + mechanical design)

- Engineering and prototyping

- Testing and certifications (if needed)

- Tooling (like injection molds)

- Initial inventory and shipping

You can control costs by starting with a focused feature set, choosing materials wisely, and working with partners who already have vetted factories and processes.

Can I create a product if I’m not a designer or engineer?

Yes. Many successful products are led by non-technical founders. Your main job is to:

- Deeply understand the customer and the problem

- Make clear decisions and trade-offs

- Pull in the right experts at the right time

You don’t have to design CAD files yourself—you just need to be able to explain what “success” looks like and respond quickly to options from your design and engineering team.

Do I need to quit my day job to develop a product?

Not at first. Many entrepreneurs:

- Validate the idea and customer demand on nights and weekends

- Work through early research and basic prototypes in their spare time

- Set clear time and money limits so the project doesn’t drift

You may need to go full-time later—usually when you’re committing real money to tooling, inventory, and a launch plan that needs your full attention.

How many units should I order in my first production run?

Your first order should be as small as you can reasonably make it while still:

- Meeting the factory’s minimum order quantity (MOQ)

- Getting a realistic per-unit cost

- Having enough units to test real-world demand

Think of the first run as a large-scale test, not “the big one.” It’s better to sell out and reorder than to sit on a warehouse full of inventory you need to discount.

When should I start looking for investors or outside funding?

You’ll have better conversations with investors once you can show:

- A clear description of the product and target customer

- Early validation (waitlist, preorders, prototype feedback, or test sales)

- A realistic cost and pricing model

Many founders fund early research and prototypes themselves, then raise money when they’re closer to tooling and production, or once they’ve proven real demand.

Should I launch with one product or a full product line?

For most first-time founders, start with one hero product:

- It’s easier to focus your budget and attention

- You learn faster from real customer feedback

- You reduce the risk of being stuck with multiple SKUs that don’t move

You can always add variations (sizes, colors, accessories) after you know what’s working.

How can a partner like Gembah help me create my product?

A partner like Gembah can plug in at every major step: research, design, prototyping, sourcing, manufacturing, and supply chain. That means you’re not trying to find and manage designers, engineers, and factories on your own, and you get a single team that helps you go from idea to shelf while reducing risk, time, and cost.