You’ve got a brilliant idea for an electronic product, but how do you turn that vision into reality? That’s exactly what we’ll explore in this comprehensive guide to electronics prototyping. Whether you’re developing a new smart home device or revolutionizing an existing product category, understanding the complete prototyping process can mean the difference between success and costly setbacks.

Key Takeaways

- Professional electronics prototyping is crucial for product success, combining rapid iteration with systematic validation to prevent costly mistakes during mass production.

- Strategic prototyping partnership selection is essential, focusing on partners who offer comprehensive services from initial concept to mass production transition.

- Different prototype types (proof-of-concept, functional, and appearance models) serve distinct development phases, with each playing a vital role in validating technical feasibility and market potential.

- The transition from prototype to mass production requires careful attention to Design for Manufacturing (DFM) principles and certification requirements, typically needing 5-10% of total manufacturing volume for validation testing.

- Modern prototyping tools and software have made electronic product development more accessible to entrepreneurs, while professional testing facilities remain crucial for ensuring market-ready products.

The Foundation of Successful Electronic Product Development

Electronics prototyping bridges the crucial gap between idea formulation and actual product development, serving as the cornerstone of successful electronic products. The journey from concept to final product involves several intricate stages, each demanding meticulous attention and expertise. Through rapid prototyping, developers can keep pace with the rapid evolution of semiconductors and ever-growing customer expectations for technological advancement.

Understanding the Real Value

Think about it this way: every successful electronic product you see on Amazon or in stores started as a prototype. The production process isn’t just about getting from A to B – it’s about systematic validation and refinement. Vector Blue Hub and similar prototyping services have helped countless entrepreneurs navigate this complex journey successfully.

Cost Efficiency in Development

Cost-efficiency is crucial for electronic prototyping. The commercial viability of your product heavily depends on the cost-effectiveness of its development process. Smart investment in rapid prototyping and leveraging efficient strategies leads to substantial savings and better resource allocation throughout the product development cycle.

The Complete Electronics Prototyping Process

Initial Concept Development

Before diving into circuit design and soldering, you need a rock-solid foundation. This first step in the prototyping stage involves:

- Comprehensive market research to validate your concept

- Detailed analysis of technical requirements

- Clear definition of product specifications

- Assessment of commercial potential using tools like Technical Level Mapping

Key Components and Considerations

PCBs and semiconductors form the backbone of electronic product development. A PCB serves as more than just a physical board – it’s the foundation that connects and supports all electronic components. Understanding different board types used in prototyping (breadboards, stripboards, and perf-boards) is crucial for successful development.

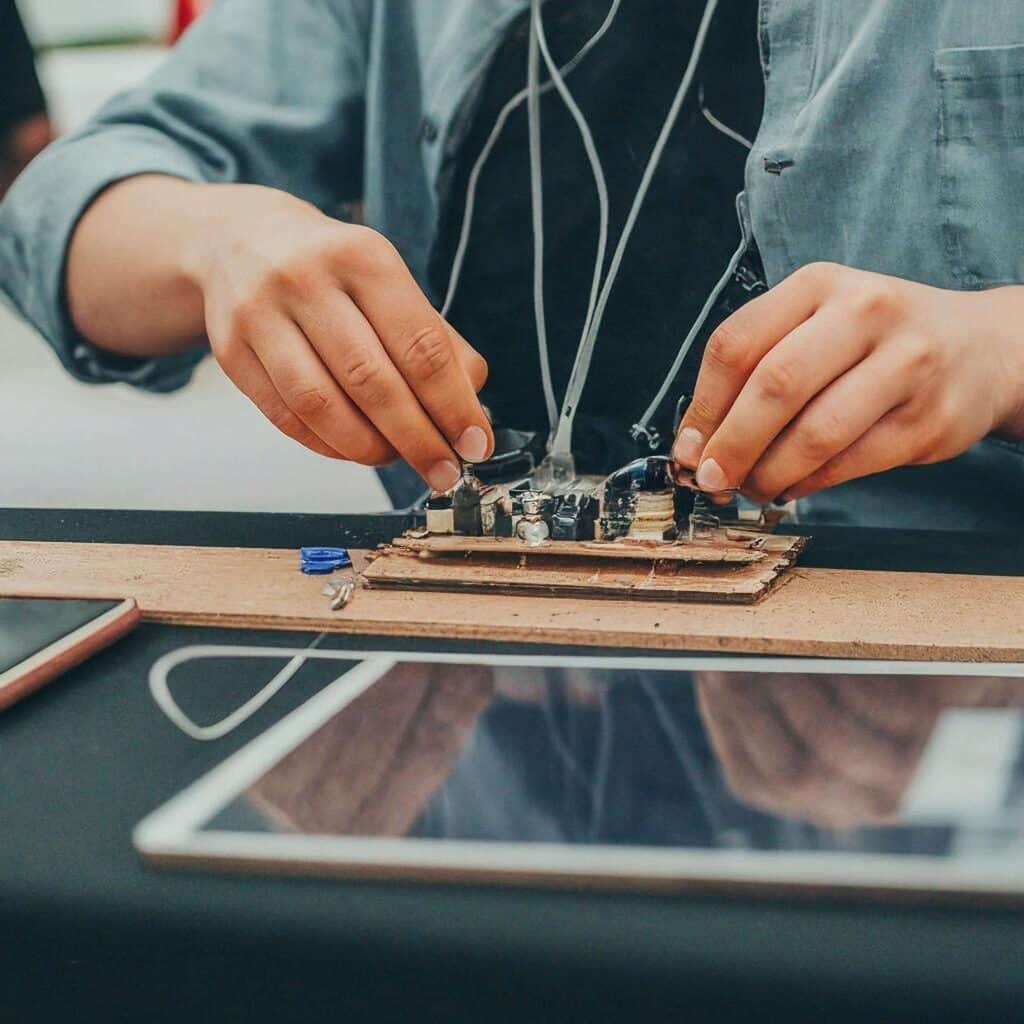

Moving from Concept to First Prototype

The journey from concept to your first electronic prototype demands meticulous planning and execution. Programming circuit design might seem daunting, but modern tools have made this process more accessible than ever. During this prototyping stage, you’ll need to create detailed schematic designs that align with your specifications while carefully selecting components that meet your prototype’s requirements. Many successful developers rely on industry-standard CAD software like DipTrace, Altium Designer, or KiCAD to bring their designs to life.

The Power of Rapid Prototyping in Modern Development

Rapid prototyping has transformed how entrepreneurs and businesses bring electronic products to market. This approach accelerates development through quick iterations and refinements of electronic systems. By enabling fast feedback loops and adjustments, rapid prototyping helps you identify and solve problems before they become costly issues in mass production.

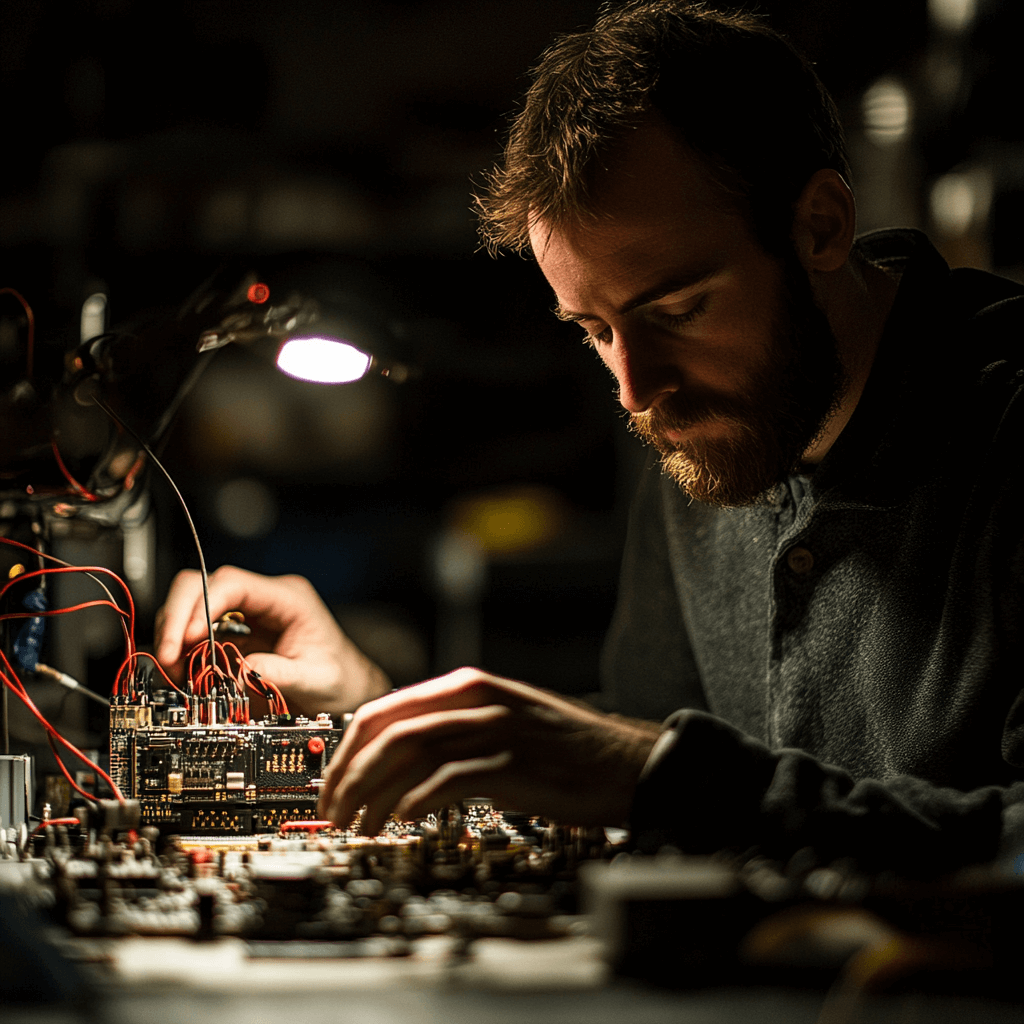

Testing and Validation

Every prototype requires thorough testing before moving toward mass production. This critical phase encompasses performance evaluation against specifications, user interface testing, and comprehensive design validation. You’ll need to collect and analyze user feedback systematically, conduct component stress testing, and when applicable, perform environmental testing to ensure your product can withstand real-world conditions.

Types of Electronic Prototypes

Different phases of development require different types of prototypes. Understanding each type helps you choose the right approach for your current needs:

- Proof-of-Concept Prototypes: These basic prototypes focus purely on demonstrating core functionality rather than final design aesthetics. Vector Blue Hub specializes in creating these early-stage prototypes that prove technical feasibility. Many developers leverage off-the-shelf development boards like Arduino or Raspberry Pi at this stage, allowing them to validate their concepts quickly without significant investment.

- Functional Prototypes: As you progress toward mass production, functional prototypes become increasingly important. These models combine working technology with design elements to create a near-final representation of your product. They play a vital role in the Design for Manufacturing (DFM) process, quality control validation, and acceptance standards testing. Through market validation, these prototypes help ensure your final product will meet real customer needs.

- Appearance Models: Demonstrating your product’s look and feel often needs to happen before finalizing the electronics. These models serve crucial roles in marketing presentations, investor pitches, and user experience testing. Your appearance model helps stakeholders visualize the final product and provides valuable feedback about design elements before committing to costly tooling or mass production.

Advanced Tools and Techniques for Effective Prototyping

Software and Simulation Tools

Modern electronic prototype design relies heavily on sophisticated software tools. The most successful developers typically utilize 3D design modeling software for visual representation, paired with circuit simulation tools for electrical validation. PCB design software guides board layout decisions, while manufacturing simulation tools help plan for eventual production. This comprehensive software ecosystem helps identify and resolve potential issues before they manifest in physical prototypes.

Cost-Efficiency Strategies

Here’s what successful entrepreneurs prioritize when budgeting for electronic product development:

- Essential investments: Component selection, development tools, and testing equipment

- Strategic partnerships: Prototyping services, manufacturing relationships, and technical expertise

- Long-term planning: Scaling considerations, certification requirements, and market entry costs

Partnering with Professional Services

Choosing the Right Prototyping Partner

When evaluating prototyping services under one roof, look beyond basic capabilities to find a true development partner. Whether you choose Vector Blue Hub or another provider, your ideal partner should understand your vision and support your entire development journey. The right partner brings comprehensive electronic prototype design services, deep experience with your product type, and clear communication protocols. Most importantly, they should be able to support you through the transition to mass production, ensuring your prototype can be manufactured efficiently at scale.

Preparing for Mass Production

Design for Manufacturing (DFM)

The transition from prototype to mass production requires careful attention to manufacturability. Your product’s design must be optimized not just for functionality, but for efficient production at scale. During this phase, manufacturers often suggest design modifications to enhance producibility. Large enterprises frequently face unique challenges when scaling prototypes to mass production, making advanced prototyping strategies essential for preventing costly setbacks.

Pre-Production Validation

Before launching into full production, thorough pre-production testing becomes vital for identifying potential defects. Industry standards typically recommend allocating 5-10% of total manufacturing volume for Production Validation Testing (PVT). This critical stage occurs before full-scale production begins. Smart entrepreneurs use this phase to also develop product packaging and marketing materials, ensuring everything aligns perfectly for market launch.

Certification and Compliance

Navigating certification requirements stands as a crucial step in bringing your electronic product to market. Different regions maintain varying standards, but they generally focus on three key areas: safety, electromagnetic compatibility, and environmental impact. Understanding these requirements early in your development process can prevent costly delays and ensure smooth market entry.

Common certifications include CE marking for European markets, FCC certification for the United States, and UL listing for safety standards. Early engagement with certification bodies often streamlines the approval process and helps mitigate potential risks that could impact your production timeline.

Real-World Success Stories

Startup Innovation in Action

Consider the story of a small team that designed a revolutionary digital handheld transceiver specifically for kite surfers. Through careful prototyping and iteration, they transformed their initial concept into a successful product that now dominates its niche market. Their experience demonstrates how proper prototyping can help startups validate their ideas and refine their designs before committing to expensive mass production runs.

Look at GoPro’s journey – they spent over ten years bootstrapping their way to success, using early market trends and rapid prototyping to perfect their action cameras. Their story underscores how crucial prototyping is for startups, allowing them to test and refine ideas before major market launches.

Maximizing Your Prototyping Investment

Strategic Planning for Success

When developing an electronic product, strategic planning becomes your foundation for success. Start by defining clear objectives for your prototyping process. Consider both immediate needs and long-term goals for your product development. This approach helps optimize your per unit costs of producing prototypes while ensuring each iteration brings value to your development process.

Time Management in Product Development

Time management proves crucial throughout the prototyping stage. Successful entrepreneurs understand that rushing through prototyping often leads to costly mistakes later in mass production. Instead of viewing prototyping as a hurdle to overcome, see it as an investment in your product’s future success. Each iteration provides valuable insights that can improve your final product.

Essential Tools for Modern Prototyping

Development Platforms and Software

Today’s electronic prototype design services leverage sophisticated development platforms that streamline the creation process. Advanced CAD tools, simulation software, and integrated development environments work together to accelerate product development while maintaining quality. These tools help identify potential issues early, reducing the likelihood of problems during mass production.

Testing Equipment and Facilities

Professional testing facilities offer capabilities beyond what most startups can establish internally. Vector Blue Hub provides comprehensive testing services that help validate your electronic product against industry standards. This level of testing proves essential for ensuring your prototype meets all requirements before moving to mass production.

Understanding Market Demands

Customer-Centric Development

Successful electronic products align closely with market needs. Through careful market research and customer feedback during the prototyping phase, you can refine your product to better meet user expectations. This approach helps ensure your final product resonates with your target market.

Competitive Analysis

Understanding your competition helps position your product effectively. During the prototyping stage, analyze competing products to identify opportunities for differentiation. This insight helps guide design decisions and feature selection for your electronic product.

Future Trends in Electronics Prototyping

Emerging Technologies

The landscape of electronic prototype design continues evolving with new technologies emerging regularly. Advanced materials, improved manufacturing processes, and innovative design tools are reshaping how we approach prototyping. Staying informed about these developments helps make better decisions during your product development journey.

Sustainability Considerations

Environmental consciousness increasingly influences electronic product development. Consider sustainable materials and energy-efficient designs during your prototyping process. This forward-thinking approach not only benefits the environment but often appeals to environmentally conscious consumers.

A Final Word on Successful Prototyping

The journey from concept to successful electronic product requires patience, dedication, and expertise. Whether working with Vector Blue Hub or another partner, remember that thorough prototyping serves as your foundation for success. Each prototype brings you closer to a market-ready product that meets your customers’ needs and your business objectives.

Frequently Asked Questions

Understanding the Process

How long does electronic prototype design typically take?

Timelines vary based on product complexity and requirements, but most projects need 2-3 months for initial prototypes. Additional refinement cycles may be necessary before reaching your final product design.

What should I prepare before starting prototyping?

Begin with thorough market research, clear product specifications, and initial design concepts. The more prepared you are, the more efficiently your prototyping services can assist you.

How do I protect my intellectual property during development?

Work with reputable partners who offer confidentiality agreements. Consider patent protection for unique innovations, and document all development stages carefully.

Making Smart Choices

How do I choose between different prototyping methods?

Consider your product’s complexity, budget constraints, and timeline requirements. Professional prototyping services can help evaluate which approach best suits your specific needs.

What’s the typical investment needed for prototyping?

Costs vary widely based on product complexity and requirements. Working with experienced partners helps optimize your investment while ensuring quality results.

Remember, successful electronic product development combines technical expertise with strategic planning. Through careful attention to each stage of the process, you can create products that not only work well but succeed in the market.