Access expert prototyping services to bring your ideas to life through Gembah’s network

Our extensive network of prototyping experts and advanced technologies help you transform your product concepts into functional, testable prototypes in record time. From 3D printing and CNC machining to electronic prototyping and user testing, we connect you with a full suite of services to validate your design and prepare for manufacturing.

We support your project at all stages of development, from market research to manufacture-ready engineering drawings.

Prototyping Milestone 1

Concept Refinement

Before diving into prototyping, we connect you with experts who work closely with you to refine your product concept, ensuring that it meets your functional, aesthetic, and user experience goals. They’ll help you identify potential design challenges and opportunities for improvement, setting the stage for a successful prototyping process.

Overview

- Product concept review and analysis

- Identification of key features and functions

- Design challenge assessment

- Collaborative concept refinement sessions

- Initial design sketches and mock-ups

A clear, well-defined product concept that forms the foundation for the prototyping process.

Identification of the essential features and functions that will be the focus of prototyping efforts.

Proactive identification and mitigation of potential design challenges, reducing the risk of delays or setbacks.

Sketches and mock-ups that bring your refined concept to life and guide the subsequent design and prototyping stages.

Prototyping Milestone 2

Computer-Aided Design (CAD)

With your refined product concept in hand, we’ll connect you with skilled designers who will create detailed 3D models and technical drawings using state-of-the-art CAD software. These digital designs will serve as the blueprint for your prototype, ensuring accuracy, precision, and manufacturability.

Overview

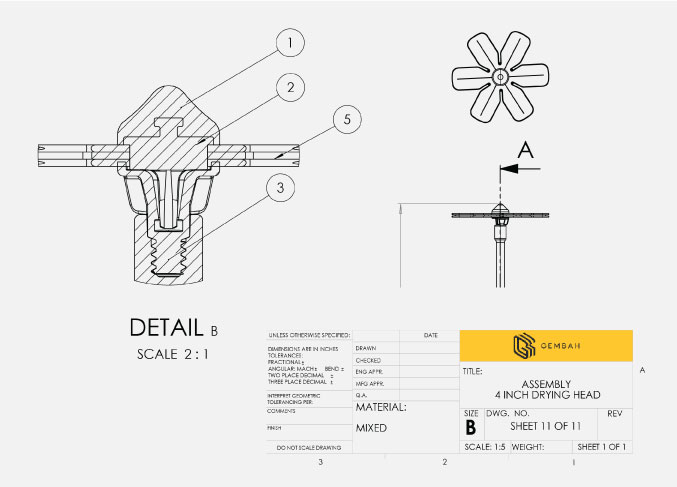

- 3D modeling and design

- Detailed part and assembly drawings

- Material and finish specifications

- Design for manufacturability (DFM) considerations

- Collaborative design reviews and iterations

Precise, high-fidelity 3D models of your product, including individual parts and complete assemblies.

Comprehensive technical drawings that specify dimensions, tolerances, and other critical design details.

Clear definitions of the materials, colors, and finishes to be used in your prototype and final product.

Incorporation of DFM principles to ensure your design can be efficiently and cost-effectively manufactured at scale.

Prototyping Milestone 3

Rapid Prototyping

Using your CAD files, our network of prototyping experts will bring your design to life using the latest rapid prototyping technologies. From 3D printing and CNC machining to electronic prototyping and silicone molding, we connect you with the tools and expertise to create functional, high-fidelity prototypes that accurately represent your final product.

Overview

- 3D printing (FDM, SLA, SLS)

- CNC machining and milling

- Electronic prototyping and PCB fabrication

- Silicone molding and casting

- Post-processing and finishing

Tangible, working prototypes that demonstrate your product’s key features and functions.

Prototypes that accurately represent your specified materials, colors, and finishes, allowing for visual and tactile evaluation.

For products with electronic components, fully functional prototypes that validate circuit design and performance.

The ability to quickly produce multiple prototype iterations, enabling fast design refinement and optimization.

Prototyping Milestone 4

Functional Testing

With your prototypes in hand, we’ll connect you with engineering experts who will conduct rigorous functional testing to validate your product’s performance, reliability, and durability. They’ll put your prototypes through their paces, simulating real-world use cases and environmental conditions to identify potential weaknesses and areas for improvement.

Overview

- Performance testing and validation

- Stress and durability testing

- Environmental testing (temperature, humidity, etc.)

- Failure mode analysis and troubleshooting

- Iterative design improvements

Confirmation that your product meets or exceeds its intended performance specifications.

Verification that your product can withstand the stresses and strains of real-world use.

Validation of your product’s ability to function reliably in a range of environmental conditions.

Identification of potential failure modes and implementation of design improvements to enhance reliability and durability.

LapLok: Securing Success through Precision Prototyping

A Prototyping Partnership Guided by Gembah

Protecting Laptops On-the-Go

LapLok collaborated with Gembah to connect with prototyping experts for their innovative laptop security device, designed to prevent theft and provide peace of mind for remote workers and travelers.

With 140 unique parts and complex functionality, LapLok required precision prototyping to ensure flawless performance. Gembah connected LapLok with prototyping experts who worked tirelessly to create prototypes that met LapLok’s exacting specifications, iterating and refining the design until it was ready for production. The result was a game-changing product that has already garnered significant interest from security-conscious companies and consumers.

Paul and Ryan Angott

LapLok Co-Founders

The Gembah Prototyping Process

Discover how Gembah’s end-to-end prototyping process helped LapLok bring their innovative laptop security device from concept to reality, ensuring a successful product launch and satisfied customers.

Concept Refinement

Gembah connected LapLok with experts to refine their product concept, identifying key features and potential design challenges.

Computer-Aided Design (CAD)

We facilitated collaboration with skilled designers who created detailed 3D models and technical drawings of the LapLok device, incorporating design for manufacturability principles.

Rapid Prototyping

Gembah connected LapLok with state-of-the-art 3D printing and CNC machining technology providers to create functional, high-fidelity LapLok prototypes for testing and validation.

Functional Testing

We arranged for engineering experts to conduct rigorous performance, durability, and environmental testing to validate the LapLok design and identify areas for improvement.

User Testing & Feedback

Gembah facilitated user testing sessions with target customers, gathering valuable feedback to inform final design iterations.

Design for Manufacturing (DFM)

We connected LapLok with manufacturing experts to optimize the design for production, ensuring efficient, cost-effective manufacturing at scale.

Pre-Production Prototypes

Gembah arranged for the production of pre-production prototypes using the final materials and production processes, providing a final validation before manufacturing handoff.

Ma Fête: Celebrating Success with Gembah Prototyping

Prototyping Perfection for Party Products

Ma Fête partnered with Gembah to connect with prototyping experts for their innovative themed party boxes, designed to make it easy for parents to create memorable, hassle-free celebrations. With Gembah’s guidance and network of prototyping specialists, Ma Fête was able to transform their themed designs into tangible, functional products that exceeded expectations.

Crafting the Perfect Party Products

Gembah connected Ma Fête with a prototyping team that worked closely with them to create prototypes that accurately represented their themed designs, including complex die-cuts and custom illustrations.

Ensuring Production-Ready Designs

Through iterative prototyping and testing with Gembah’s network of experts, Ma Fête refined their designs for optimal manufacturability, ensuring a smooth transition to production.

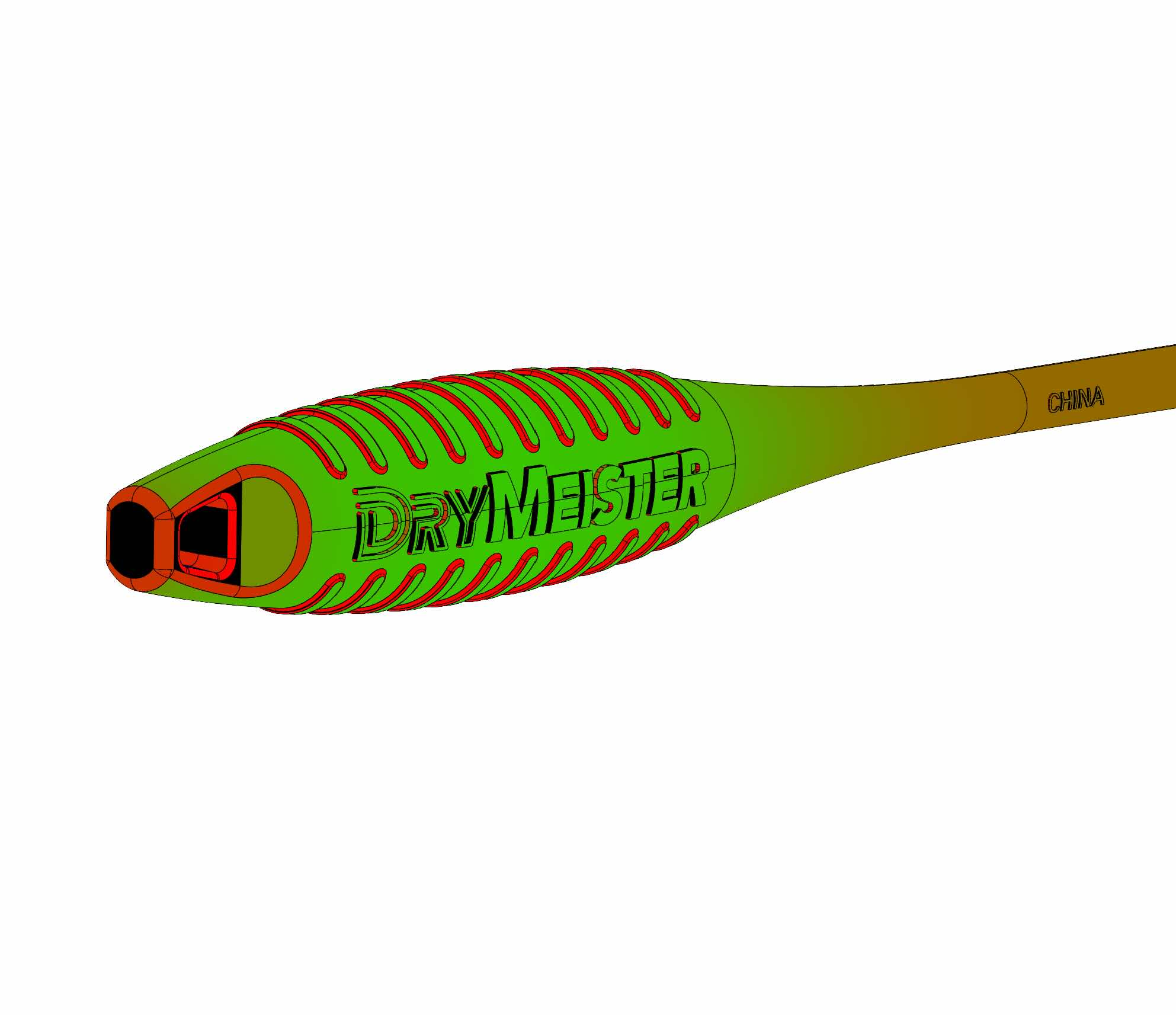

Crochet Hook

Furls Crochet

Milk Frother

MUDWTR

Mighty Spatula

Smithey

Camping Bowl

Rigwa

Baby Bibs

Babylist

Swaddle

The Ollie World

Baby Sling

Tuck & Buckle

Activity Bags

Keke Bags

Pup Stack

Pup Stack

Treat Purse

Cocoa & Onyx

Bite Pillow

Operation Good Boy

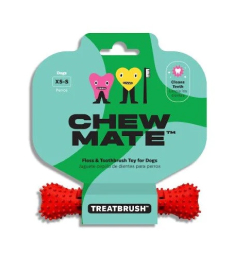

Dog Toy

Chew Mate

Weighted Jewelry

Cali Weights

Bluetooth Speaker

BlueTees

Heated Furniture

Outmore Living

Resistance Bands

Corefirst

We’re thrilled with the final version of the Pup Stack. After working through several iterations and design changes we built our first prototype. ..Then we built another. And another. Aaaaand another to get every last detail just right.”

We’ll connect you with skilled designers to transform your concepts into detailed 3D models and technical drawings, ready for prototyping.

From 3D printing and CNC machining to electronic prototyping and silicone molding, we’ll connect you with the tools and expertise to bring your ideas to life.

We’ll arrange for engineering experts to put your prototypes through their paces, ensuring they meet your performance, reliability, and durability standards.

We’ll guide you through the process of optimizing your designs for manufacturability, ensuring a smooth transition from prototyping to production.