When new businesses fail, most of the time, it’s due to running out of cash. Poor cash flow management is the nemesis of the more than 80% of new ventures that fail in year one.

It takes much capital to get started, no matter what vertical or industry you’re trying to enter. One of the highest costs of any new business is equipment: Fundera estimates that entrepreneurs should budget $10,000-$125,000 for their first year’s equipment costs alone.

If you’re manufacturing a product, that range can skyrocket, which is why savvy entrepreneurs outsource their supply chain to manufacturing companies overseas.

Here are some great reasons outsourcing product manufacturing can help your business survive its first year and grow profitably.

Better budget management

“Reducing costs is the number one reason why companies outsource. 59% of companies surveyed cited cost reduction as their motivation for putting this into practice,” writes Entrepreneur.

Outsourcing to a manufacturing company leads to cost-savings across the board – not just in equipment expenses. As one expert outlines, “savings can be realized in reducing labor costs, overhead maintenance costs, and distraction and redundancy costs.” Many regions around the world offer lower labor costs and use their facilities to serve more than one company. These decreased labor costs mean you benefit from lower maintenance and utility costs in addition to wages and salary expenses.

But, cost-savings are just part of the equation. Outsourcing also gives you the power to manage your budget and prevent overspending. Many manufacturing companies offer a pay-as-you-go model.

This model allows your business to grow at your own pace. You can test the market, hone in on your target audience, and check business assumptions to make sure the demand is there.

As a result, your startup can be proactive in managing supply to meet demand, lowering your deadstock, and inventory management costs.

Gain expertise

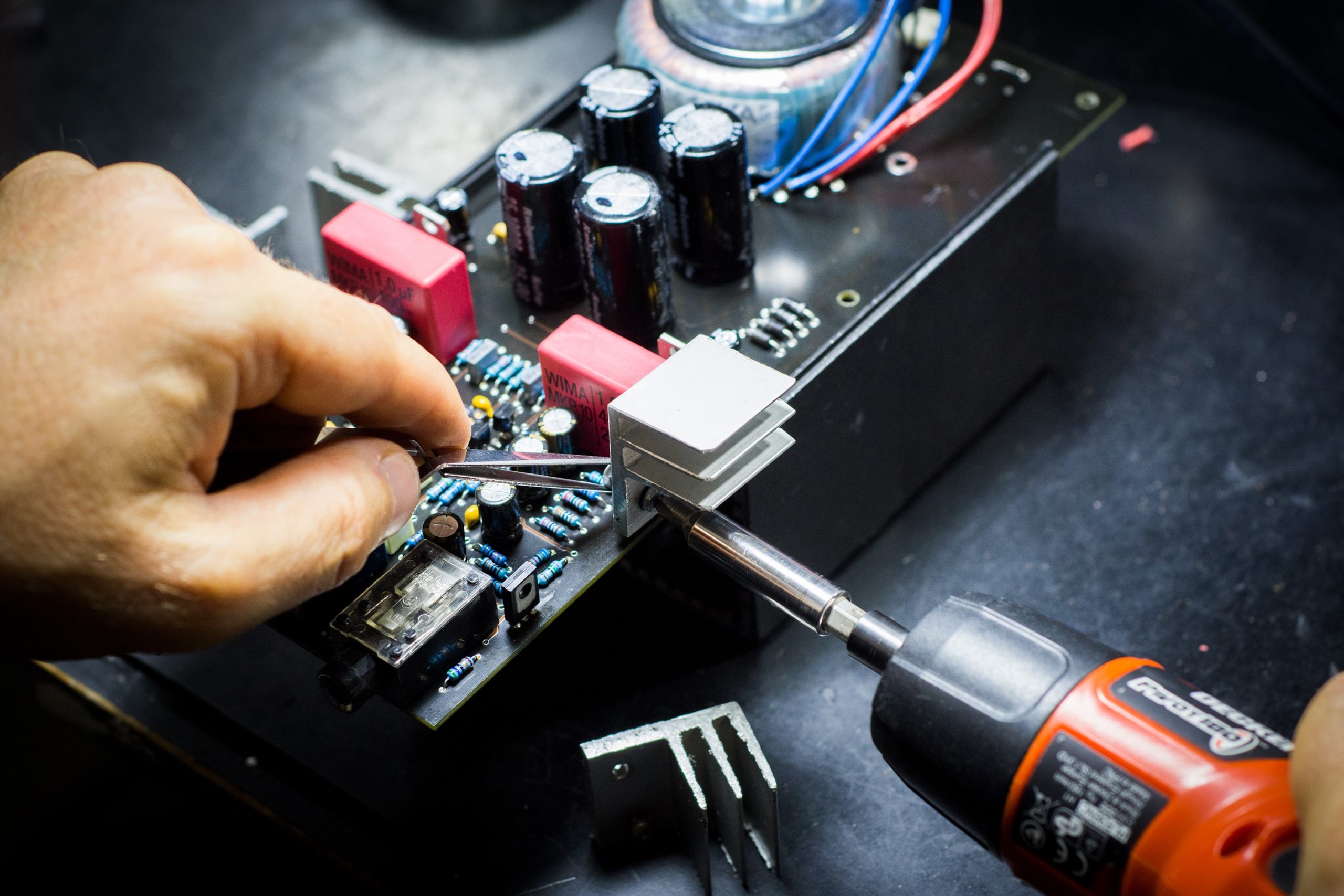

It’s unlikely as a startup, one of your first hires is someone with deep quality control and manufacturing expertise. Few new ventures have an in-house engineer or technician who can take a prototype from initial design to fruition. Even fewer new ventures have the resources to visit the factory, conduct quality control, and make sure all is moving according to plan.

The right manufacturing company will bring expertise to the table to help you develop your product the way you had envisioned. These partners have more experience than your average entrepreneur in product quality, cost savings, and supply chain management.

Some partners help throughout the production process by:

- Sending you photos along the way

- Managing the logistics and compliance of your shipping order, and

- Performing quality control, so you don’t have to

These partners add value to your team and take on work by which your core employees would otherwise be distracted.

Go to market faster

“Outsourcing manufacturing to an overseas company equipped with the proper resources and personnel allows businesses of all sizes to compete at the international level. This approach allows smaller companies the chance to partner up with multi-million dollar production powerhouses, removing limitations on their potential,” writes one blog.

When you have a good idea, it’s crucial to be first-to-market.

Outsourcing to a manufacturing company cuts down on time it takes to be the first one on the scene. Consider the process of manufacturing in-house: first, you have to find a space, then procure equipment, then materials and labor.

By the time you’ve manufactured your prototype, your competitive advantage has disappeared. Instead, work with an existing factory that can take your plan and turn it into a product with speed and scalability.

Iterate with flexibility

Outsourcing your manufacturing allows you to move quickly and respond to demand as the market changes. “Prototyping and other production-related functions can be boosted to allow for innovation without draining internal resources,” writes one expert. “When a sudden uptick in demand occurs, outsourcing allows manufacturing operations to scale up rapidly.”

For more mature companies, outsourced manufacturing is a quick and easy way to expand outside your core offering. If you want a low-risk way to test a product, order a small batch based on your initial prototype to see how customers respond.

The right partnership will give you a window to change elements of your design throughout the process. As you develop and grow your product offering, your fixed manufacturing costs aren’t going to fluctuate dramatically.

Learn more about outsourcing production and how Gembah can make the process easy.