It’s a cold hard fact in the world of fashion product design: It doesn’t matter how amazing your design is if your manufacturer doesn’t make it exactly how you want it. All that time researching, iterating, and prototyping goes out the window when you get a final product that doesn’t match your vision. That is why having a fashion tech pack — a complete product definition — is essential.

If you’re bringing new garments, bags, and shoes to market, you need to understand the ins and outs of this critical document package. Whether you’re on the creative, technical, or business side of the team, everyone has input into the tech pack, and everyone is responsible for making it as complete as possible.

In this article, we’ll explain what a tech pack is and go into some details on why it’s so important. We’ll provide pointers on what makes a great tech pack great and then offer advice on how to make it happen.

What Is a Tech Pack?

A tech pack, or technical pack, contains all of the technical information your manufacturer needs to create the finished product. It’s “technical” because it’s not the creative aspects of the design. A tech pack is the master document that tells your manufacturer what you want and how to make it.

Let’s take a look at what is in a tech pack to get a better understanding of what one is:

-

- Product code or style number: This is a unique identifier for each style of your product. It can include year, season, color, fabric options, and size.

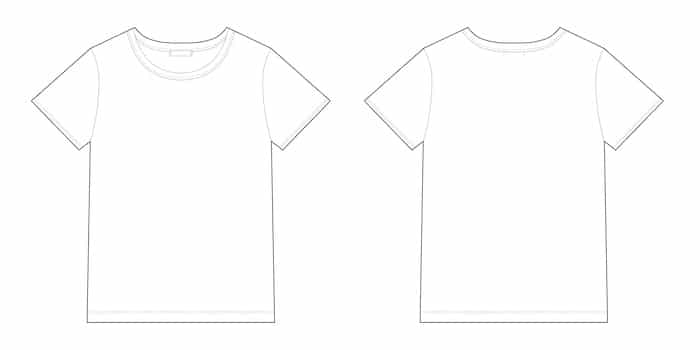

- Flat sketch: This is a 2D black-and-white drawing of the product. It includes front and back views and, if needed, a side view. It is usually black and white, and all proportions are accurate. Sometimes you add color to the product design sketch, called a colorways spec. The flat sketch may also be called technical drawings, technical flats, or fashion flats.

- Color specifications: This section captures the color of each part of the product. It lists specific industry standard details for color and shade.

- Fabric details: This section contains as much information about the required material as possible. It may be a particular material, including the provider and product number. Or it may be more general, giving requirements like weight, cost range, print, wash requirements, and allowable shrinkage. Include a swatch when possible.

- Stitching and construction details: This is where you specify how to put the product together, down to the stitch type, thread, class, and length. It also defines the order of assembly for your product.

- Print details: If your material has any print on it or texture, you need to define it in this section. Define the pattern, colors, and location of the print pattern on the product with a drawing.

- Embroidery details: If your product includes any decorative stitching, you define the pattern, location, material, and colors here.

- Washing details: The manufacturer needs to know how you expect your customers to clean the product. Document everything that must go on the care label.

- Trim details: This is where you detail everything that goes on your product except the fabric. It specifies buttons, zippers, thread, beading, clasps, rivets, etc. It also includes materials for packaging, like the bag the product may go in and pins needed to secure the folded product.

- Point of Measurement (POM): The flat sketch defines the shape of your product, and the POM specifies which key dimensions to measure for each size. They are drawn on the 2D flat pattern and measured on the flat garment.

- Size chart and grade rules: This section contains a table that gives the value of each POM for each size. The grade rules are also in this section.

- Bill of materials: This is a list of all items making up the product — each panel of fabric, the trim, and the packaging. It lists the name and, if known, the supplier.

- Label details: This section defines what labels are needed, their size, content, and where they go.

- Folding and packaging details: Last but not least are instructions on how to fold and package the product.

- Other information: The product type and your manufacturing partner determine the other details in the tech pack. They may include testing requirements, cost details, quality control requirements, samples needed before production, and shipping instructions.

This list is pretty typical, but tech packs vary across the industry. Nevertheless, it should provide your manufacturer with everything they need to quote and make your product in all the sizes and styles you order. While there is some redundancy, that’s OK. Putting information in multiple places makes it easier for the people planning your manufacturing.

A portion of the tech pack may be your spec sheet or specification sheet. The term harkens back to when all the parts of a design needing inspection could fit on one page. These days, it’s rarely one sheet and contains the flat sketch, POM, placement details, and sizing information — everything required for inspection.

A lot of companies create their tech packs in Microsoft Excel. They will use Adobe Illustrator to make the drawings and figures. However, there are software tools designed to simplify and standardize the process.

Why Are Tech Packs Important?

Let’s examine each to better understand the benefits of a tech pack for your clothing line, footwear, or fashion accessory.

Accurate Quoting

Before you commit your company to production, you need to know how much it will cost to make your product. And, if you’re selecting a clothing manufacturer, you want accurate quotes from multiple providers. If you give manufacturing a comprehensive tech pack, they will have all the information they need for a precise quote.

Correct Manufacturing

The reality of manufacturing is you get what you ask for. Who knows what you’ll end up with if you’re unclear on any details. The fabrications of soft goods can vary a lot, mainly because skilled labor is often needed to make the products. Without a detailed tech pack, your manufacturer will have to guess what you want.

Quality Control

Another age-old maxim in manufacturing is you get what you measure. That’s why your tech pack needs to include the information required for quality control. The tech pack tells your quality control team what’s mission-critical, how they should measure, and what values are allowable.

Saving Money

For all the reasons above, a tech pack saves you money. You get accurate quotes and don’t have as much correction and rework. Furthermore, tech packs reduce the number of samples you need. Without a factory-ready tech pack, you’ll have to pay to create a fit sample, review it and issue revisions, then make another sample — iterating until you get it right. With the proper tech pack, the fit sample becomes a verification step rather than an iterative process.

Time is everything in the fashion industry, and time is money. Focusing on a great tech pack will reduce your time to market.

What Makes a Great Tech Pack Great?

Here are some suggestions for creating a tech pack to make your production process run smoothly:

- Make sure your drawings are accurate and clear.

- Provide CAD versions of the drawings so the pattern makers don’t have to redraw the shapes.

- Establish a tech pack template, and use it for every line you produce.

- Ask your manufacturing partner for a list of what they expect in a tech pack or an example of a “perfect” tech pack.

- Include fabric samples if possible.

- Identify suppliers if you want to go with a specific fabric or trim item.

- Include creative details for reference like mood boards, pictures of your prototypes, and fashion design sketches.

- Try to put yourself in the shoes of the person quoting or making the product and think of what additional information you would need.

- Record any feedback you get back and add that information to your tech pack template.

Work With the Right People to Create a Great Product and a Robust Tech Pack

A great place to start is to partner with Gembah and our network of experts. We have considerable experience in the fashion industry and can assist in finding a manufacturing partner, managing the manufacturing process, and even helping with the design. It doesn’t matter if you are introducing a new T-shirt or if you have a full fashion brand, Gembah’s team of experts is ready to be part of your journey. Reach out today, and let’s talk about how we can help.