Production Management

Manufacturing operations management is about making sure the final product matches the designs, and the production schedule is met.

Keep Your Production on Point

Even if you have the best factory in the world, you could end up with a shipment of defective products if you don’t take precautions. What do you do if 20%, 50% or 90% of your product is unsellable? Can you get the factory to replace it? Can you wait months for the new shipment to arrive? In that case, what you really need is a time machine.

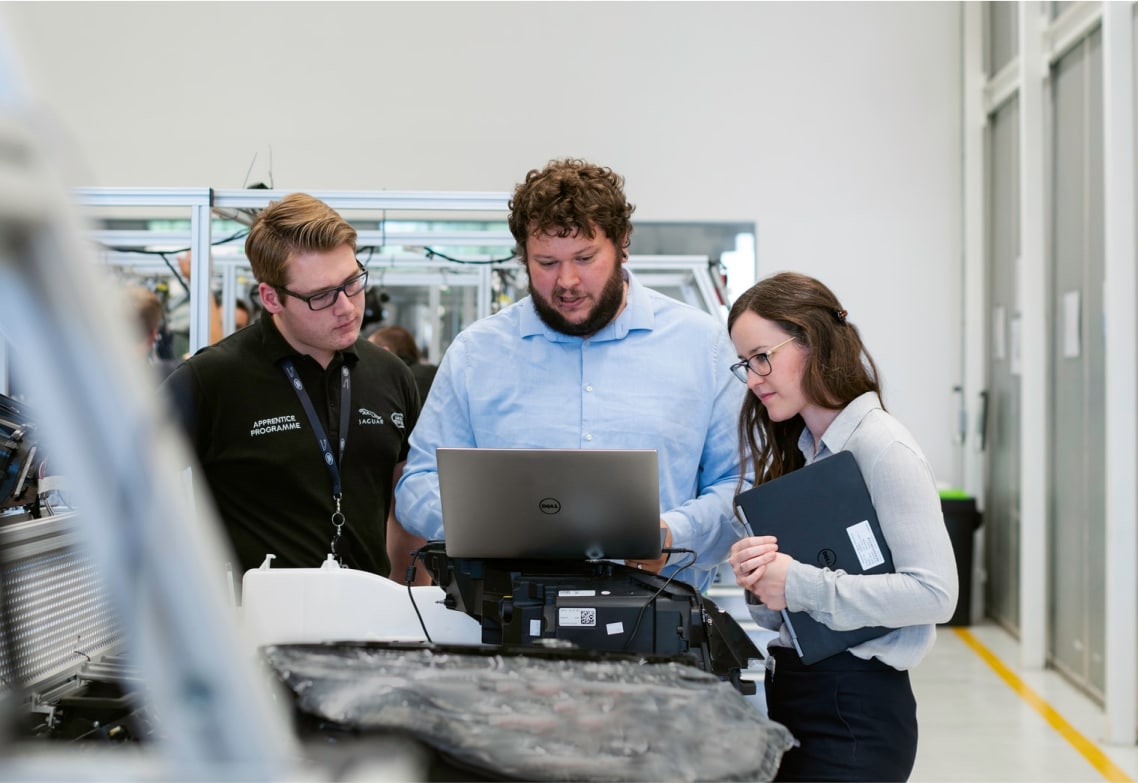

Production and operations management is absolutely essential to ensuring your product comes out right. Our inspectors are your on-the-ground representatives, analyzing your product’s quality run just as you would. They oversee the entire production process, so you can stay focused on building your brand at home.

Production Management

A Crash Course in Quality Control

Ahead of the full production run, our team visits the factory in-person to collect and review samples, conduct testing, and keep you constantly up to date. When manufacturing begins, we return at multiple points for quality control analysis, and send you a report with photos and videos. You track your production and make recommendations based on what’s happening in real time from your office (or home… or the beach).

Step 1

Production Sample

By the time the assembly of your product is rolling, you will already have received a production sample from the factory. Assuming that came out right, they get to work on completing the order. We’ll work with you to determine the possible points of failure so we can test them upon our return.

Step 2

Design & Functionality

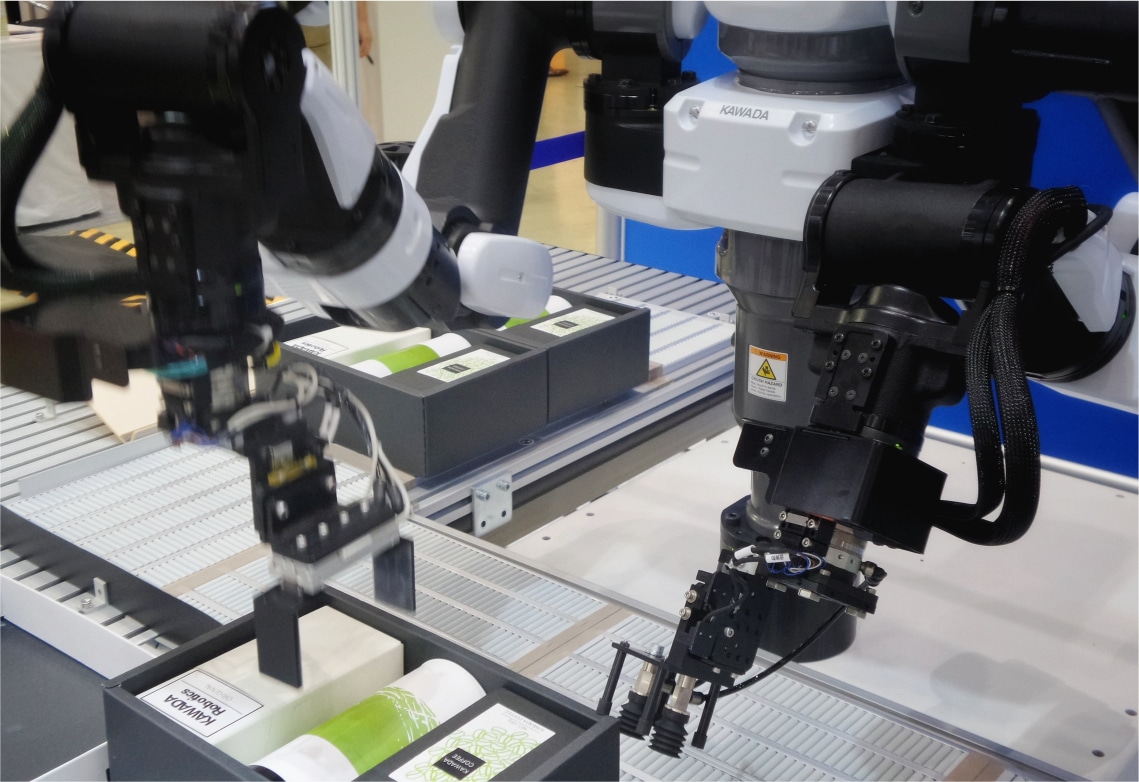

Once about 80% of the order is complete, our testers come back for a design and functionality scan. We visually inspect it while taking photos and videos so you can see the results in real time. Then the testers use it how a customer would, checking that it functions as intended.

We go beyond the basics, down to the packaging. Most third-party testers won’t package a product up then drop it off a ladder. Ours will, because your product is going to have to survive some rough handling before it makes it to you then the customer. We send you videos of these tests so you can see for yourself. If we find defects at any point, we can work with the factory to resolve the issue and replace the damaged goods.

Step 3

Final Quality Check

After the order is 100% complete, we check your products before you go through the expense of having them shipped. We get deep into the details––down to checking the spelling on all the packaging. If the production run passes quality standards, it’s good to go. If not, we sort it out.

A Necessary Precaution

Managing the manufacturing process during production is the only way to be certain your entire order comes together as planned. Evaluating and testing products early on lets us fix potential defects before your entire production run is complete.

Our inspectors follow AQL standards when determining whether the quality of the factory’s output is acceptable. These are the internationally accepted criteria, which means the manufacturer is obliged to comply whenever we demand they replace defective products and increase the overall quality of the production.

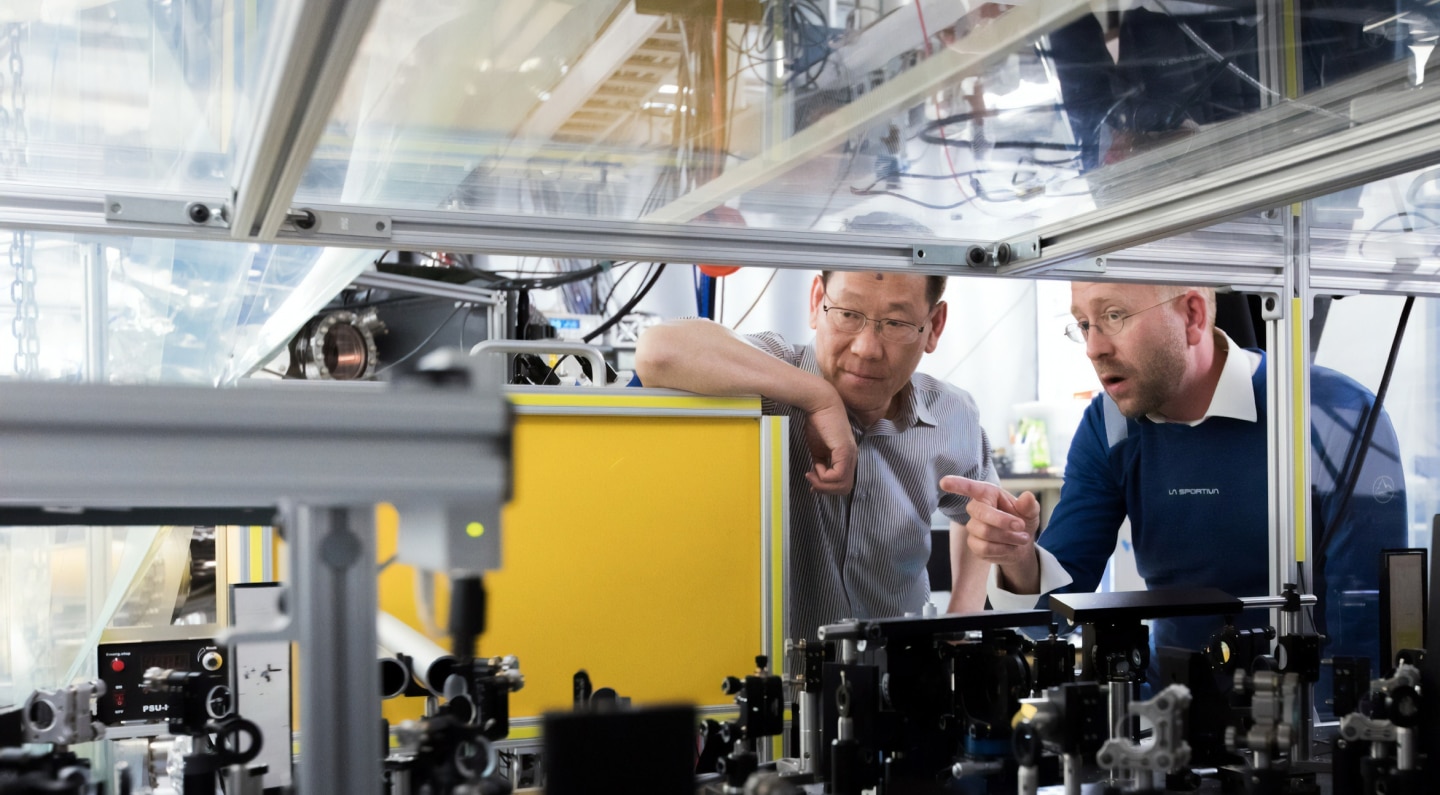

Our Testers Are Simply Better

Whoever is testing your product on your behalf should have extensive experience in your product category. That’s a given. Our testers go beyond what a third-party inspector can accomplish. Rather than acting as an intermediary between you and the factory, they’re operating as a member of your team. They understand your product vision and can tell when it is or isn’t being met.

A typical inspector will test your product on a basic scope that you set with them. That’s all they report on. They don’t understand your ambitions for the product like we do. They can’t analyze the subjective qualities that determine whether it matches your intentions. Anyone can see if a product works or not, but the quality of a product isn’t determined simply by how it functions. You can’t encapsulate quality in a series of yes or no questions. Our inspectors understand that. If you designed with us, sourced with us, we are going to see your vision through to the end.