Creating a new product is hard. That’s why some of the most successful companies in the world use lean product development to turn market needs and innovation into products that customers want. By reducing waste and increasing the efficient transfer of knowledge without stifling innovation, lean product development delivers better product performance, faster time to market, and increased profit.

Dozens of successful companies, including Toyota, Harley Davidson, Intel, and Goodyear, use this approach to product development. Case studies detailing their successes and failures abound on the internet. Formulated initially by Toyota, lean methodology in research and development (R&D) is an excellent approach for new businesses seeking to maximize customer value with the least amount of waste.

Here’s what entrepreneurs need to know about lean product development.

Background: the History of Lean Product Development

Lean product development (LPD) and lean manufacturing both originated at the Toyota Motor Company in the second half of the 20th century. The Toyota Production System established lean manufacturing, a way to systematically identify and eliminate waste through continuous improvement focused on what customers want. The system evolved through many years as Toyota worked on making high-quality automobiles and reducing costs. The Toyota Production System revolutionized manufacturing and introduced the ideas of Jidoka and just in time manufacturing to factories around the world.

Jidoka is the idea that systems, a plant, or a single machine should be set up to turn off if any errors are detected. Just in Time, or JIT, is an approach to inventory management where your entire supply chain is aligned such that the items you need for a given step shows up right when you need them. It eliminates the waste of having supplies sitting around in inventory.

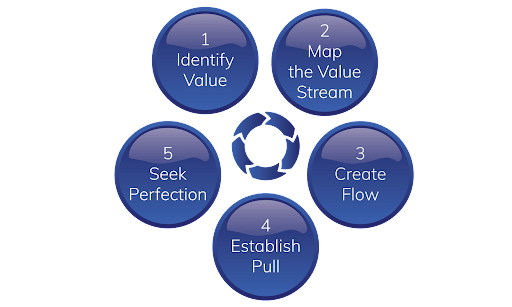

The success of this approach evolved amongst those who studied efficiency into the idea of lean principles that could be applied to all aspects of business:

- Identify value

- Map the value stream

- Create flow

- Establish pull

- Seek perfection

Toyota recognized the way it designed automobiles could benefit from these principles as well, so they started to apply the lean principles, ideas they developed in the Toyota Production System, to incrementally improve their product design capabilities.

Over time, they developed guidelines for project management that became what we now call lean product development. As other companies attempted to solve the problems inherent in most product development processes, they adapted and modified lean thinking to fit their industry and products best. In a nutshell, the resulting approach focused on the lean principles of reducing waste and creating value based on customer needs.

Principles of Lean Product Development

The varying needs of different industries make it difficult to define a set process for product development. The most significant difference between lean manufacturing and lean product development is the need for flexibility. Because of this, LPD focuses on fundamental principles that companies can adapt and modify to fit the needs of each product development cycle.

These principles dictate how an entrepreneur or new business can apply the lean design approach to deliver customer value and minimize inefficiencies. The following is a list of the most common principles applied to product development projects:

- Understand and capture value: The fundamental goal of a lean process for new product development is to ensure that every effort focuses on adding value. To do that, the development team must understand the value of every step in the value chain and capture that information in metrics that can be measured and improved upon.

- Eliminate waste: Waste includes anything which does not provide value to the end-user. Once value is understood, team members can identify and remove any tasks that do not contribute to the value of the product for the customer.

- Create and capture knowledge: Knowledge takes many forms and can be innovation, resources, or processes. Creating knowledge is fundamental to any product development system. And if that knowledge is not captured and used again, it is waste.

- Use concurrent engineering: Concurrent engineering is a way to work in parallel while capturing and exchanging knowledge. This can be used to explore multiple solutions for a single challenge or to work on different challenges at the same time. It also captures what development teams learn so they can hand off that information simultaneously or in the future. Many different project management methods can be used for concurrent engineering, including agile, waterfall, and kanban.

- The project plan should be a value stream: A value stream is a theoretical and ideal set of tasks that add value so that the customer will recognize that value and pay for it. Any tasks that do not add value are removed from the project plan.

- Set up a process that pulls information through the value stream: Traditional product development processes push information from one task to another and stops the flow of information at phase gates. In lean product development, the project management team establishes a project plan which pulls information along the value stream.

- Aim for perfecting the product and the process: The application of continuous improvement methodologies is fundamental to adding value and reducing waste. At every step, every participant in the product development process should be iterating and experimenting to improve the value of each step in the process. Capturing and sharing those improvements is also fundamental to continuous improvement.

Large enterprises or new companies can use any combination of these principles. And the approach of lean thinking can be applied to other areas of a startup or the entire organization.

“The Lean Startup,” a 2011 book about product development, outlines how to avoid building a product that no one wants or needs by adapting Toyota’s original lean development principles.

In software development, the agile approach to project management is another example of applying lean principles to remove waste, increase customer value, and get to market faster. And of course, the lean manufacturing method can be used for product manufacturing.

In today’s competitive economy, applying a lean product development approach can reduce cycle time during the critical design phase of your product lifecycle and dramatically improve your company’s chance of launching a successful product. LPD gives your product design team a toolset to reduce waste and focus on adding value for customers.

How to Use Lean Product Development

Lean product development begins by considering what specific value your product or service can provide for customers. What problem are you solving by developing this product? Do market research and competitive analysis to capture product-market fit and to make sure the demand for what you have to offer genuinely exists. This is often called value stream mapping.

Next, incorporate the principles of holistic optimization and involve all stakeholders from the outset. As a new company, you should also identify a partner with an experienced team that utilizes a lean product development strategy. Find a partner that can work with your business from product design through sourcing to production management and logistics.

Also, remember that knowledge capture, collaboration, and communication are fundamental to eliminating waste and increasing product value. One common way to make sure that all three things happen, and something that Toyota feels is key to their implementation of lean product development, is creating the position of chief engineer. This person controls the whole process, ensuring that information is pulled and knowledge is captured and communicated. If you don’t have a chief engineer, partner with a company like Gembah that does.

Once you get started, make sure that you leverage concurrent engineering and have processes in place to calculate and capture value for use immediately and in the future. Your chief engineer should work with the entire team, both in-house and your partners, to continuously improve the product and the process used to innovate, test, and define your product.

Finally, repeat the process until you’ve achieved perfection. Perfection, as defined by lean product development, is “measurable value with no waste.” It’s a highly sustainable, profit-building method for product development. Inevitably, this approach benefits both consumers and brands.

Innovate Value that Customers Will Pay For

Learning about lean product development, putting processes in place, and then changing your organization’s mindset to embrace this proven approach can deliver significant competitive advantages. Even as a startup or with a brand new product, you can achieve lower development costs, faster time to market, and a product designed to meet customer needs that customers will perceive as having significant value. These, in turn, drive better profits while increasing your brand value and easing your funding journey.

If you’re ready to start this journey and need a partner who understands and uses lean product development every day, the experts at Gembah are ready to talk.