Manufacturing in the USA

How to evaluate if US manufacturing is an alternative for you

Explore options for onshoring your manufacturing

Key considerations when considering manufacturing in the US

High tariffs on Chinese goods are growing incentive to source elsewhere. Now, after the US election, tariffs on goods imported from any country may be a reality soon, further boosting the desire for brands to manufacture in the US.

US manufacturing costs are still too high for most companies. Despite tariffs, US manufacturing is still too expensive for most brands and e-commerce sellers, except for very specific use cases.

Country specialties

Popular Sectors of US Manufacturing

The United States is home to some of the most advanced and innovative manufacturing capabilities in the world. With a strong emphasis on quality, technology, and sustainability, American manufacturers excel in producing high-value, complex products across a wide range of industries.

The U.S. leads in biotechnology and pharmaceutical manufacturing, with advancements in precision medicine, medical devices, and biopharmaceuticals.

The U.S. is known for producing advanced polymers, industrial chemicals, and sustainable green chemistry products.

High-end consumer products, including appliances, artisanal items, and premium electronics, are manufactured with a focus on quality and craftsmanship.

The aerospace and defense sectors are key strengths of American manufacturing, producing aircraft, defense systems, and space technology.

Advanced Manufacturing: The U.S. is a global leader in advanced manufacturing technologies, including robotics, AI, 3D printing, and smart factory solutions.

The United States is at the forefront of automotive innovation, from electric vehicles to autonomous driving technology and traditional automotive production.

Tariff Changes Are Reshaping Global Manufacturing —

What Small Businesses Need to Know

This Free White Paper Covers:

Tariff Policy Changes & Impact

Understand recent U.S. tariff shifts and their effects on small businesses.

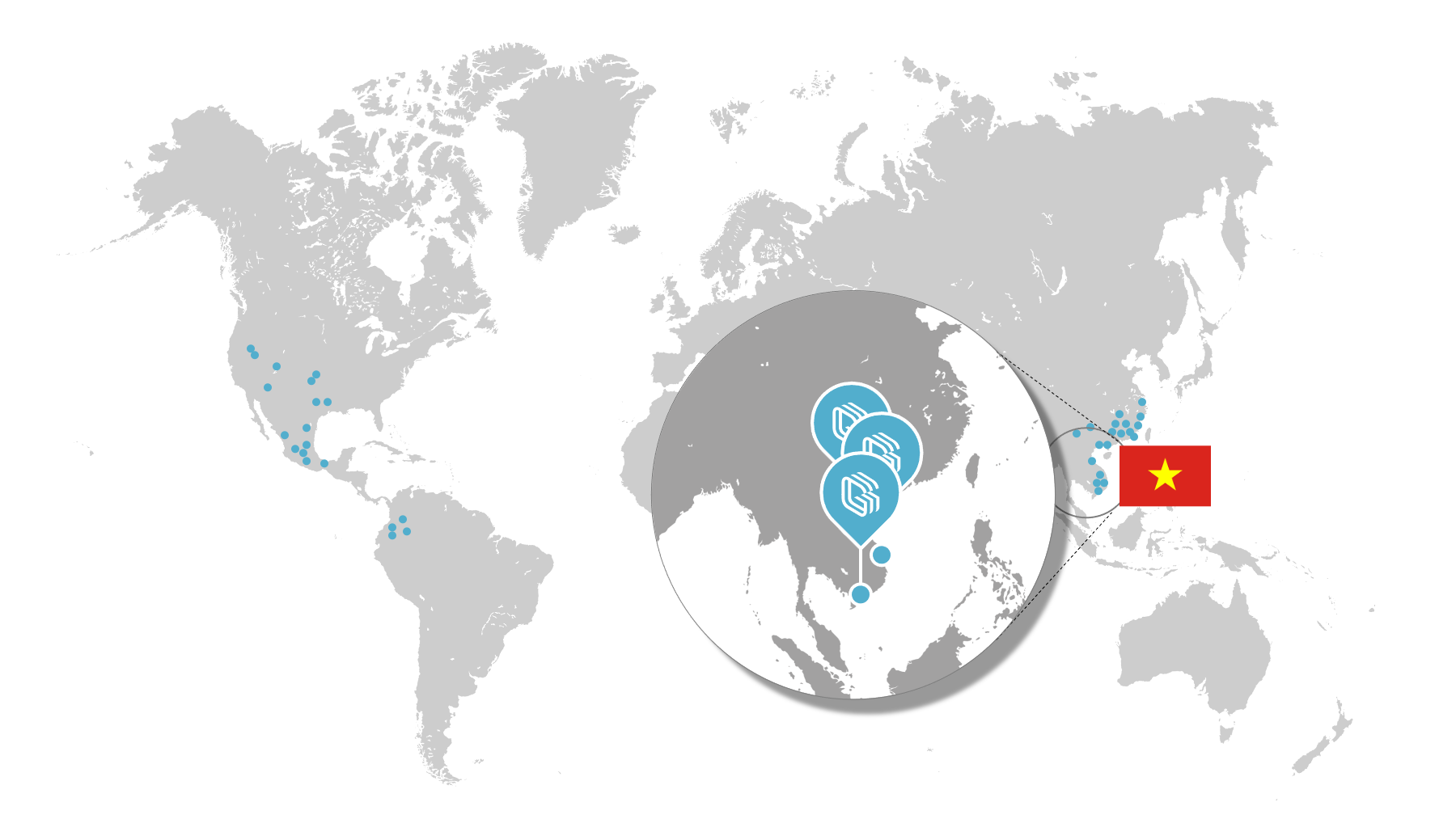

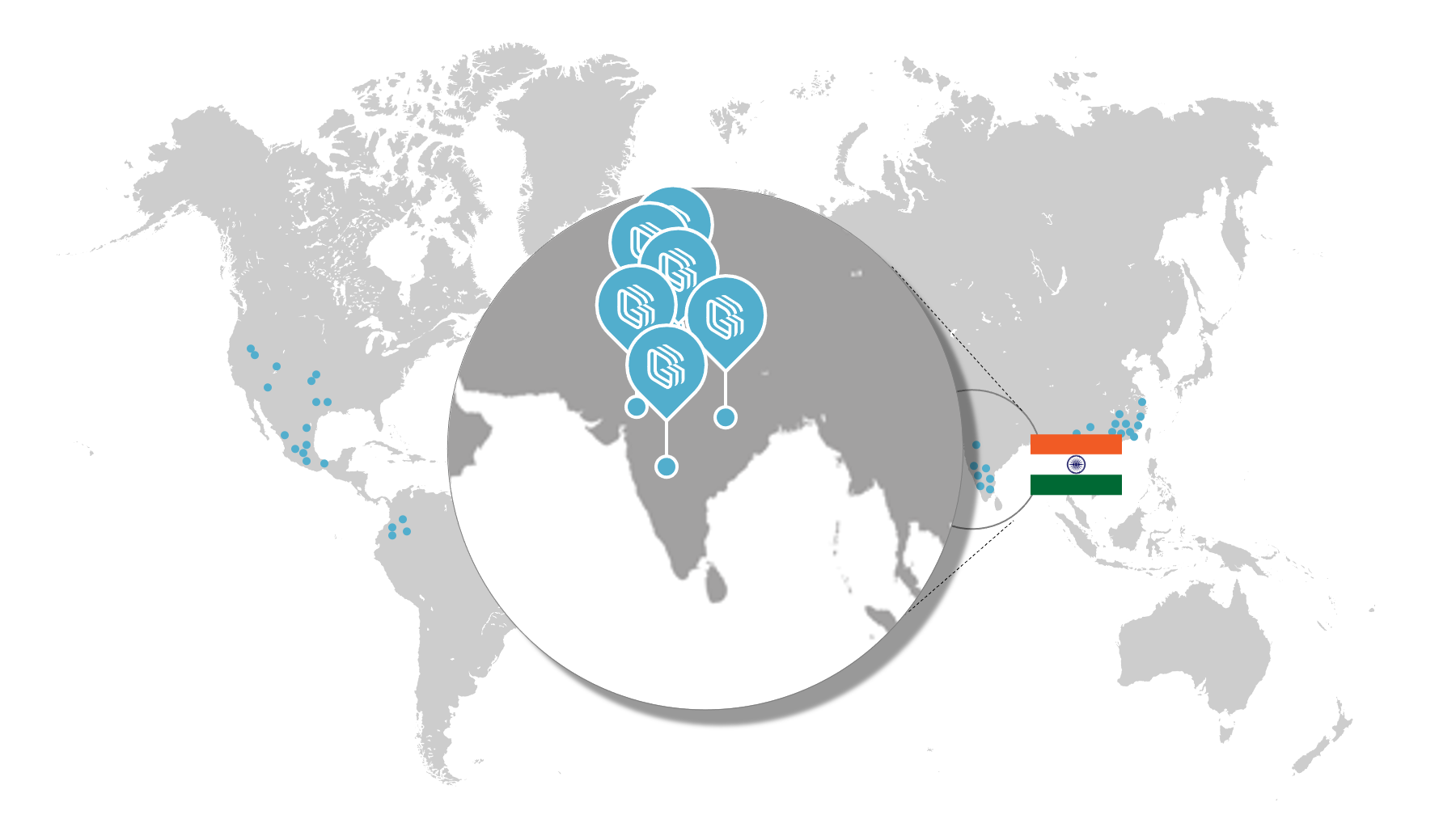

Manufacturing Alternatives

Explore cost-effective production options in areas like India, Vietnam, and Mexico.

Actionable Strategies

Learn how to navigate tariffs, optimize supply chains, and reduce total costs.

Your Free White Paper Will

be in Your Inbox Shortly!

How TO MANUFACTURE IN THE US

Examples of when US manufacturing can work

for US SMBs and e-commerce sellers

If your product is linked to any of the following areas contact us to talk about options for USA manufacture

For companies that target customers who value American-made products, especially in premium or luxury segments, such as clothing, furniture, manufacturing in the US can be a marketing asset.

If the product requires frequent design updates or is made in small batches, the flexibility of US manufacturing can offset the higher costs.

Products like high-end furniture, where high shipping costs from Asia help offset higher labor cost in the US, and access to high-quality domestic hardwoods

Similarly, heavy products like cast iron cookware, grills, or smokers also have high shipping costs from overseas, and can leverage access to high-quality domestic raw materials

Manufacturing in the USA – Key Considerations

Understand the Advantages, Challenges and Strategic Insights for having your product idea made in the USA

Made in the US is growing in popularity

Significantly higher labor cost than overseas typically leads to higher landed cost

Reduced shipping costs, tariffs, and time in transit

Higher costs lead to potentially lower margins or higher consumer pricing, narrowing the market

Increased quality control & ability to visit factories

Limited options and flexibility, for many products you cannot find a factory in the US that can make it

Join the 100s of solo inventors and big brands partnering with gembah

How we help ensure manufacturing success between you, designers & quality factories in the USA

With over 2000 factories in the Gembah Network. We bring designers and factories together in a unique development process that targets saving you time and cost getting to market.

Supply Chain Solutions

Supply chain Solution begin with our expert factory network.

Factory Discovery

Find the perfect factory match for producing your products, followed by providing support during price negotiations to ensure you get the best possible deal.

Sampling & Tooling

Receiving, validating, and reviewing samples until satisfied that the quality and specifications are achieved.

Production

Manufacturing of parts, followed by rigorous quality control checks. These parts are then brought to the assembly line,

Production Management

Manufacturing of parts, followed by rigorous quality control checks. These parts are then brought to the assembly line,

The Gembah Vetting Process

We use advanced technology to identify factories with proven success in manufacturing specific products.

We review online and third-party databases to verify factory credentials and compliance.

Our team visits shortlisted factories to validate information and ensure compliance with ethical and safety standards.

Experts conduct rigorous quality checks during production to ensure products meet all specifications.

Case Studies of USA Manufacturing

With over 2000 factories in the Gembah Network. We bring designers and factories together in a unique development process that targets saving you time and cost getting to market.

Creation Technologies

Creation Technologies specializes in electronic contract manufacturing services. The company is renowned for its expertise in the custom manufacturing of complex, full-system assemblies, offering advanced engineering, test, and development solutions for high reliability applications. With 13 locations in the North

St Peter

9 Factories Across the US

4,000

Employees

Mana Products

Established in 1975, Mana Products is a leading manufacturer of cosmetics formulations. They develop and produce a wide range of beauty products, including makeup, skincare and haircare.

New York

Location

500

Employees

Product Reviews

Gembah’s track record of high quality products now in production

Milk foamer

5 stars on MUD/WTR Store

I got a mud whip with my initial starter kit and I love it so much, I bought myself an extra one.

Client: MUD/WTR

Resin Crochet Hooks

Rated 5 stars Amazon

Ooh I’m so Happy with these beautiful ommi crochet hooks.

Client: Furls Crochet

Treatbrush

Rated 5 stars in store

Chewy mate the best oral cleaner for my fur baby

Client: Chew Mate

Magsafe Readers

Rated 4.5 stars Amazon

These little readers are a very cool design. They’re so minimal! They’re perfect

Client: Pheonix Collective

Find amazing insights in the market, and develop the ideas that bring them to life.

Work with the best talent to develop your idea into a full product for manufacture.

Comprehensive solutions to support new or existing products in supply chain.

Save Time: Go -> Direct to Manufacture

Depending on your idea you might be able start working with a factory right away.

DESIGN solutions

Our most time-effective solution

If your product fits the requirements, you can take part in Direct to Manufacture, where we will introduce you to a factory to work on your design. This works amazingly for ideas that already exist. Small customisations or white labelling products where the exploration and concepting stage is already completed.

Find opportunities in the market to positively differentiate your future product, and develop amazing concepts to bring that to life.

Take all the available options you have of designing your product, and finalise them into clear specifications and design intent.

Take all the available options you have of designing your product, and finalise them into clear specifications and design intent.

Take all the available options you have of designing your product, and finalise them into clear specifications and design intent.

Finalise all the development work into a pack of drawings and specifications that allows it to be manufactured anywhere in the world.

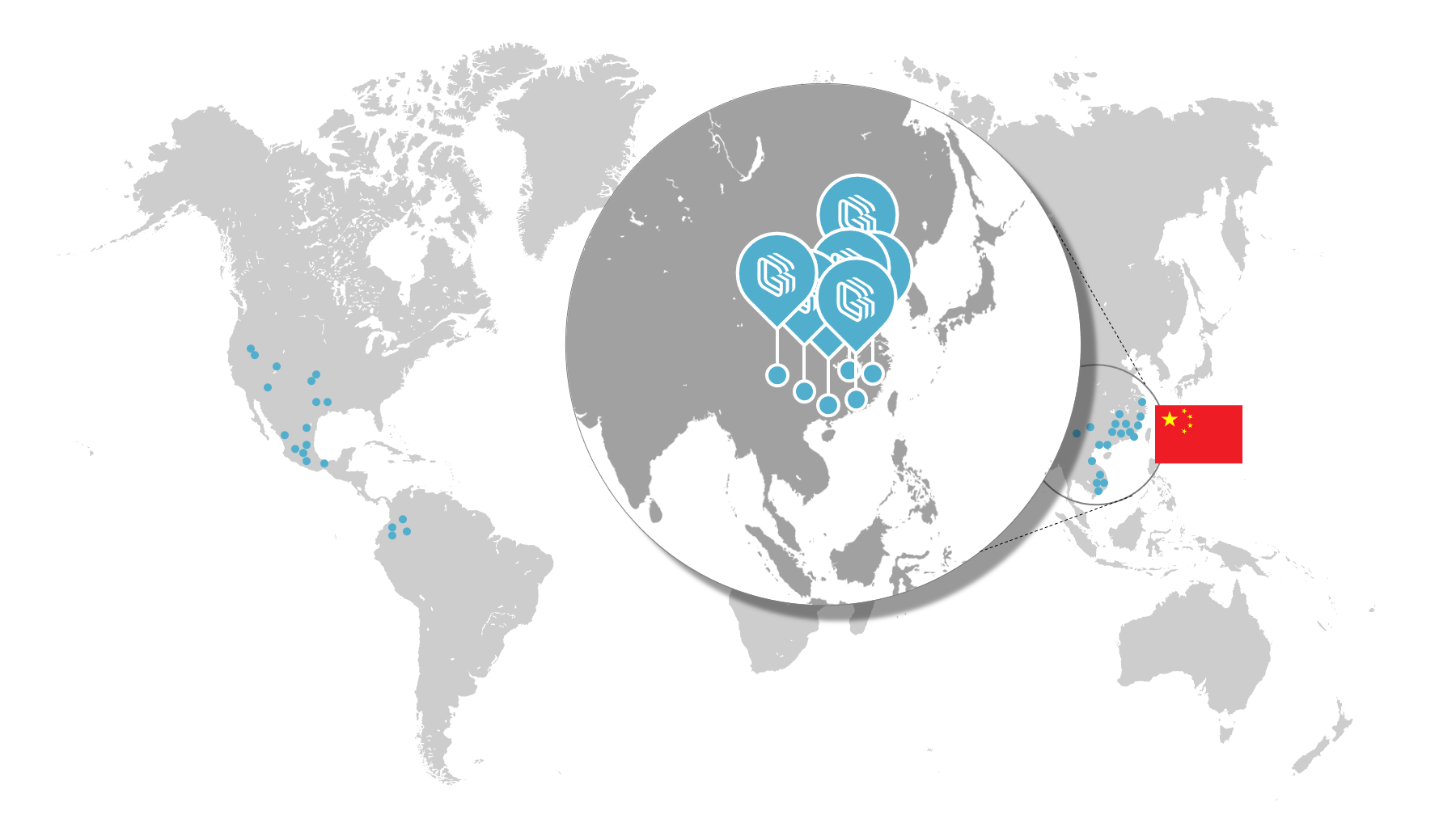

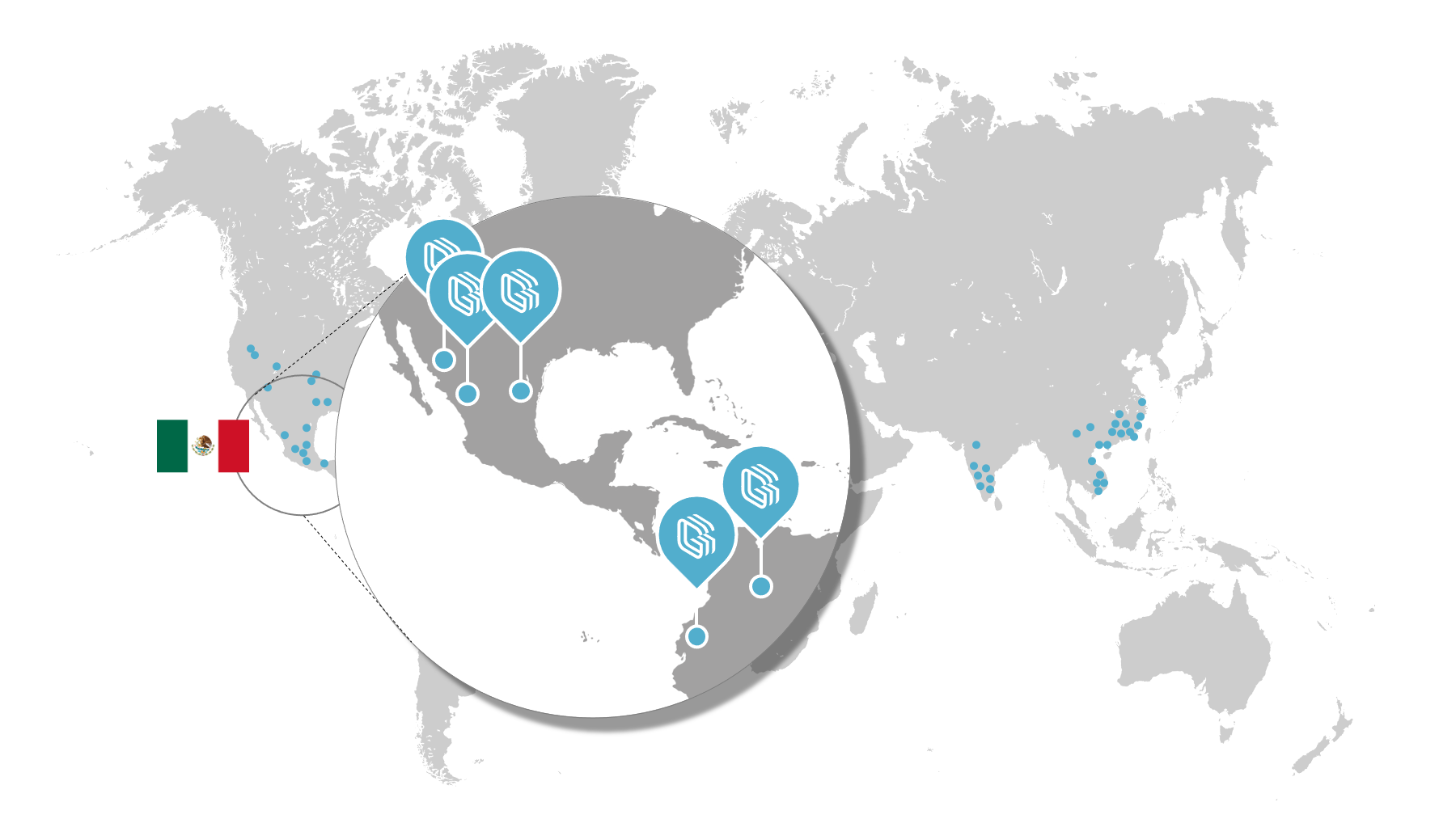

Global Sourcing

We have Gembah teams in the largest manufacturing

hubs of the world and contacts in many more.

Find amazing insights in the market, and develop the ideas that bring them to life.

Find an existing product you’d like to apply your branding to and get to market fast.

Work with the best talent to develop your idea into a full product for manufacture.

Comprehensive services to support new or existing products in supply chain..