The new product development process is a proven roadmap for taking ideas into products, and it’s used by thousands of companies across hundreds of industries every day. The steps in this process are tools that, when used properly, can deliver a true competitive advantage and increase your company’s bottom line.

The benefit you derive is directly related to how well you leverage those tools. We have a comprehensive how-to guide for new product development, but like any process, you can use it well or use it poorly. Although we don’t have any shortcuts to share, we do have some tips to pass on for getting the most out of using the NPD process. The goal is to get a better product to market faster. And it wouldn’t hurt to save some money on the way.

Below are the six suggestions for any team starting work on a new physical product. There are more, but these are the most important and apply pretty well to any industry, regardless of how simple or complex your product is.

A Review of the New Product Development Process

- Stage 1: Ideation and Research

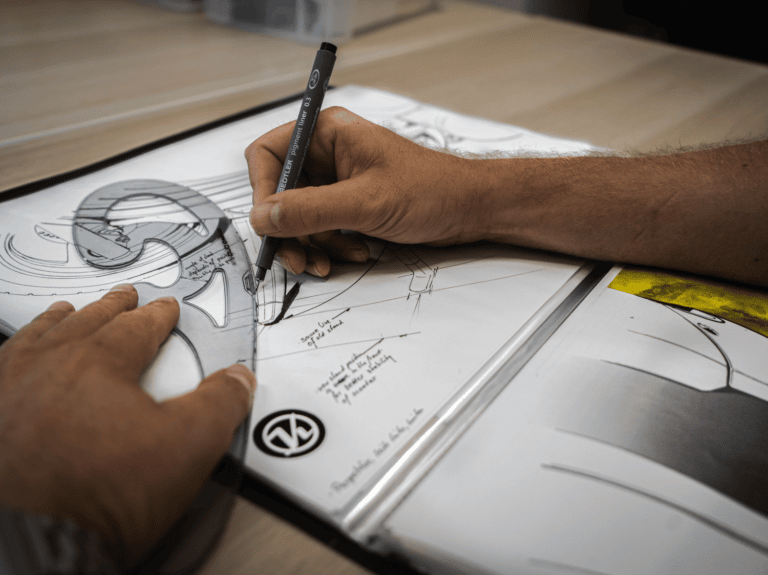

- Stage 2: Product Design

- Stage 3: Sourcing

- Stage 4: Production Management

- Stage 5: Logistics and Compliance

- Stage 6: Supply Chain Evaluation

Some people will phrase each of these differently or split the steps into more phases. But in general, any company developing, making, and selling physical products will follow this basic process.

Tip 1: Don’t Skip or Skimp on Steps

Take the time to do a complete business analysis, a feasibility study, and document your marketing strategy. And then, in design, take the time to develop a final product design that is manufacturable, addresses customer needs, and hits your cost and price goals. When you look at the other hints, you will notice they overwhelmingly address the product design phase of the new product development process — because so many people skimp during the design steps and pay in the end.

Tip 2: Use Early, Thorough Research and Prototypes to Make Changes When it’s Earlier in the Process

The best way to do this is to start with thorough research in the first phase. Spend the time and money to do market research, gather market needs, brainstorm product concepts, and validate your product idea regarding customer needs and commercialization. It’s tempting to dive into the design before this is all done, but you will have to start over again once you get all your information in one place.

Then, in the early stage of the product design phase, build prototypes as early as possible and test them internally and with target customers, or at least with a proxy product owner. The more information you get from mockups, both real and virtual, early in the process, the easier it will be for you to incorporate what you learn into the design. And don’t forget manufacturing. Sharing your prototypes with your production partners will allow them to give you feedback on design changes before spending any time or money on manufacturing processes or tooling.

Tip 3: Adopt a Lean Product Development Process

There are many ways to implement the new product development process, where the phases are the same but how your team works is different. Each approach varies how you approach creativity, problem-solving, product management, market input, collaboration, and manufacturing. One of the most effective approaches for physical products is lean product development, a method developed by Toyota and now used by many of the best companies in the world. This approach is especially popular with startups and smaller companies or teams that can work together in the iterative manner prescribed by this approach.

The principles of lean product development are:

- Understand and capture value

- Eliminate waste

- Create and capture knowledge

- Use concurrent engineering

- The project plan should be a value stream

- Set up a process that pulls information through the value stream

- Aim for perfecting the product and the process

Take a look at our article on lean product development to learn more. The goal of this approach is to work as a tightly integrated team focused on innovating value that customers will pay for.

Tip 4: Use Design for Manufacturing

The most important recommendations in DFM are:

- Have your manufacturing partner review your design and prototypes and make recommendations on improving the design to increase manufacturability and lower cost.

- Design the geometry of parts with manufacturing and assembly processes in mind.

- Minimize the number of parts in any assemblies.

- Use the same parts as much as possible.

- Design parts to minimize the amount of labor in manufacturing and assembly.

- Remove pre-processing, manufacturing, and post-processing steps.

- Minimize the need for tight tolerances.

The list goes on. The key thing to remember is to build design for manufacturing into your new product development process and make sure everyone on your development team is applying it throughout your project.

Tip 5: Focus on Creating a Minimum Viable Product

That’s why the concept of a minimum viable product (MVP) has become such a popular product strategy. Create a product with the minimum number of features, just enough to start getting customer feedback in the real world. It’s a concept developed for software development. Still, it works well in physical products, giving you valuable user feedback so that in future versions of your product, you can make tweaks to the product design to meet a greater number of market needs. An MVP is also a great way to try out your messaging and gather metrics on how well your marketing plan reaches your target audience.

Tip 6: Build a Team that Knows their Stuff and Works Together

Work With, Not Against, Your New Product Development Process

The goal of using the new product development process is to end up with a successful product that gains significant market share over the entire product life cycle. And, as the last tip points out, you can start by building the right team that knows the process and knows how to work with it.

Gembah is here to help with that. We are the world’s first global marketplace for product development. We know the NPD process, and our staff and partners can help your team make this proven method of bringing products to market work for you. Although some may describe our team and network as wizards, we don’t wear robes or carry wands. We are experienced experts backed by a global network or resources who know how to turn product ideas into product gold. Reach out today, and let’s talk about how to apply a solid new product development process to your project.